Califonia Bearing Ratio Test and its Relevance in Road Construction

Roads that crumble under traffic or runways that crack prematurely often trace their failures to one overlooked factor: subgrade strength. The California Bearing Ratio (CBR) has been the gold standard for evaluating soil stability in road construction since the 1930s. This penetration test doesn’t just measure dirt—it determines how highways, airports, and pavements withstand decades of wear. Let’s unpack why this century-old method remains indispensable.

What Is the California Bearing Ratio (CBR)?

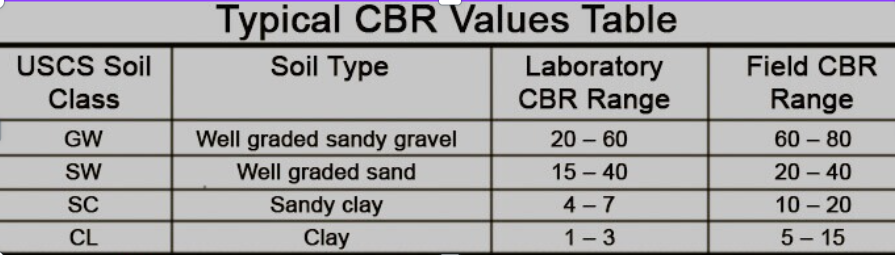

The California Bearing Ratio (CBR) quantifies the load-bearing capacity of soils and aggregates by comparing their resistance to penetration against a standard crushed-rock material. Expressed as a percentage, a CBR value of 100% means the tested material matches the strength of ideal crushed stone. For example:

Clay: 2–5% CBR

Sandy soil: 10–20% CBR

High-quality subbase: 80–100% CBR.

Developed by the California Division of Highways (now Caltrans), this test became a global benchmark adopted by ASTM, AASHTO, and the FAA.

Historical Evolution of the CBR Test

The 1920s: Birth of a Necessity

As automobile usage surged in the early 20th century, California’s road network faced unprecedented strain. Engineers at Caltrans devised the CBR test in 1928–1929 to standardize subgrade evaluation, ensuring roads could handle heavier axle loads without costly overdesign.

Standardization and Global Adoption

By 1935, California formally integrated CBR testing into pavement design. Today, it’s codified in:

ASTM D1883 (U.S.)

AASHTO T193 (transportation agencies)

BS 1377-9 (U.K.).

Why CBR Testing Matters in Road Construction

1. Subgrade Strength Assessment

Weak subgrades lead to potholes, rutting, and structural collapse. The CBR test identifies soils requiring stabilization—like clay (low CBR) versus gravel (high CBR).

2. Pavement Thickness Optimization

Higher CBR values allow thinner pavement layers. For instance:

| CBR Value | Required Pavement Thickness |

|---|---|

| 2% | 450 mm |

| 10% | 250 mm |

| 30% | 150 mm |

3. Uniformity Across Construction Sites

Testing multiple site locations ensures consistent soil conditions, preventing localized failures.

Step-by-Step CBR Test Procedure

Laboratory Preparation

Sample Collection: Soil is sieved to remove particles >19 mm.

Moisture Conditioning: Water is added to achieve optimum moisture content per Proctor test standards like ASTM D698.

Compaction:

Static Compaction: Gradual pressure application.

Dynamic Compaction: A 4.89 kg rammer delivers 56 blows per layer .

| Compaction Method | Use Case |

|---|---|

| Static | Cohesive soils (clay, silt) |

| Dynamic | Granular soils (sand, gravel) |

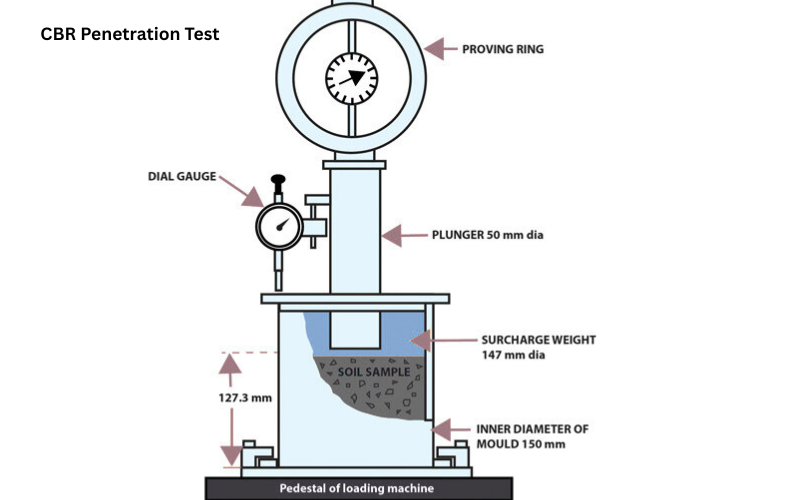

Penetration Test

Surcharge Weights: A 2.5 kg annular weight simulates overburden pressure.

Plunger Penetration: A 50 mm plunger penetrates the soil at 1.25 mm/minute. Loads are recorded at 2.5 mm and 5 mm depths.

CBR Calculation:

$$CBR\;(\%)\;=\frac{Test\;Load}{S\tan dard\;Load}\;\times\;100$$

The higher value between 2.5 mm and 5 mm penetration is selected.

Key Entities in CBR Testing

Organizations: ASTM International, AASHTO, U.S. Army Corps of Engineers.

Standards: ASTM D1883, BS 1377-9.

Equipment: CBR moulds, penetration plungers, Proctor compaction hammers.

Correlation Between CBR and Soil Mechanical Properties

Understanding the relationship between California Bearing Ratio (CBR) and other soil mechanical properties is vital for accurate pavement design and soil stabilization strategies.

CBR and Elastic Modulus (Young’s Modulus)

The Modulus of Elasticity (E), which measures soil stiffness, is often correlated with CBR to predict soil behavior under load. Research shows a strong functional relationship: soils with higher CBR values generally exhibit higher elastic moduli, indicating greater stiffness and load-bearing capacity. Finite Element Method (FEM) simulations further validate this correlation, enabling engineers to estimate soil deformation characteristics from CBR results.

| Soil Property | Relationship with CBR | Practical Implication |

|---|---|---|

| Elastic Modulus (E) | Directly proportional | Higher CBR → Stiffer soil → Less deformation |

| Resilient Modulus (Mr) | Empirical correlations developed | Used in pavement design software like IIT PAVE |

| Shear Strength (Su) | Positive correlation, varies with plasticity | Helps estimate soil failure parameters |

CBR and Resilient Modulus

The Resilient Modulus (Mr) is a key input for modern pavement design, representing the elastic response of soil under repeated loading. Empirical correlations between soaked CBR and Mr have been developed, especially for subgrade soils, allowing substitution of expensive cyclic triaxial tests with simpler CBR tests in many cases. However, these correlations are region-specific and depend on soil type and compaction methods.

CBR and Soil Index Properties

Several studies have established regression models linking CBR with soil index properties such as:

Liquid Limit (LL)

Plastic Limit (PL)

Plasticity Index (PI)

Maximum Dry Density (MDD)

Optimum Moisture Content (OMC)

For example, a strong correlation was found in soils from Nepal:

CBR=0.72×PL−1.22×PI+2.34×OMC+106.97×MDD−222.46

This equation demonstrated an R² of 0.744, indicating a reliable predictive capability of CBR from index properties, which reduces the need for extensive laboratory testing.

Soil Stabilization Techniques for Low CBR Soils

Low CBR values (<5%) indicate weak subgrades that require stabilization before pavement construction. Common methods include:

Lime Stabilization: Reacts chemically with clay minerals, reducing plasticity and increasing strength.

Cement Stabilization: Provides cementitious bonding, improving load-bearing capacity.

Fly Ash Addition: Enhances soil structure and reduces permeability.

Mechanical Stabilization: Mixing with granular materials like gravel or crushed stone.

| Stabilization Method | Suitable Soil Types | Effect on CBR |

|---|---|---|

| Lime | Clayey soils | Increases CBR by 50-100% |

| Cement | Various soils | Increases CBR significantly |

| Fly Ash | Clay and silty soils | Moderate improvement |

| Mechanical | Sandy and gravelly soils | Improves compaction and strength |

These techniques are selected based on soil type, availability of materials, and project budget.

Modern Alternatives and Enhancements to CBR Testing

While CBR remains widely used, alternative or complementary tests have emerged:

Plate Bearing Test (PBT): Measures in-situ soil bearing capacity under a loaded plate, providing direct field assessment.

Dynamic Cone Penetrometer (DCP): Offers rapid field estimation of CBR values through penetration resistance.

Falling Weight Deflectometer (FWD): Assesses pavement structural capacity indirectly related to subgrade strength.

These methods can validate or supplement CBR data, especially for large-scale projects or where rapid assessment is required.

Practical Considerations in CBR Testing

Sample Preparation: Laboratory compaction must replicate field conditions to ensure relevance.

Soaking Period: Soaked CBR values simulate worst-case moisture conditions, critical for pavements exposed to water infiltration.

Test Limitations: CBR does not directly measure shear strength or modulus but provides an empirical index; interpretation requires engineering judgment.

Summarizing Correlations and Applications

| Correlation Type | Equation / Relationship Example | R² Value | Notes |

|---|---|---|---|

| CBR vs Plasticity Index (PI) | CBR = 17.227 − 0.867 PI + 0.013 PI² | 0.682 | Negative correlation with PI |

| CBR vs Soil Index Properties | CBR = 0.72 PL – 1.22 PI + 2.34 OMC + 106.97 MDD – 222.46 | 0.744 | Strong multiple regression model |

| CBR vs Ultimate Bearing Capacity | qu = 172.6 × CBR – 601 (for CBR > 5%) | ~1.0 | Predicts bearing capacity in kPa |

| Stabilization Technique | Effect on CBR | Typical Application |

|---|---|---|

| Lime | +50-100% | Clayey soils |

| Cement | +100%+ | Various soils |

| Fly Ash | Moderate | Clay and silty soils |

| Mechanical Mixing | Moderate | Sandy and gravelly soils |

Frequently Asked Questions

Can CBR tests be performed on-site?

Yes, in-situ tests account for seasonal moisture variations but require specialized equipment

What’s the minimum CBR for a stable subgrade?

5–7% for low-traffic roads; ≥15% for highways

How does soil moisture affect CBR values?

Increased moisture content generally lowers CBR due to reduced soil strength; hence soaked CBR tests simulate saturated conditions to ensure conservative design.

Can CBR be correlated with shear strength?

Yes, empirical correlations exist between soaked CBR and undrained shear strength (Su), especially for soils with varying plasticity indices

What is the significance of soaked vs unsoaked CBR?

Soaked CBR reflects soil strength under wet conditions, critical for pavements exposed to rainfall or groundwater, whereas unsoaked CBR represents dry conditions