Proctor Test and Its Relevance in Road Construction

The Proctor Test is a cornerstone in road construction and geotechnical engineering, providing a scientific basis for soil compaction—a process that directly affects the strength, durability, and longevity of roads. Whether you’re a student or a seasoned professional, understanding the Proctor Test is essential for ensuring quality and compliance in civil engineering projects.

What Is the Proctor Test?

The Proctor Test, named after Ralph Roscoe Proctor, is a laboratory procedure used to determine the optimal moisture content at which a soil type will achieve its maximum dry density. This ensures the soil is compacted to the highest possible density, which is crucial for creating stable roadbeds and embankments.

Why Is Soil Compaction Important in Road Construction?

Prevents settlement and rutting: Well-compacted soil resists deformation under traffic loads.

Increases load-bearing capacity: Essential for supporting heavy vehicles and structures.

Reduces water infiltration: Minimizes erosion and frost heave.

Ensures pavement longevity: Poor compaction leads to cracking, potholes, and costly repairs.

Types of Proctor Tests

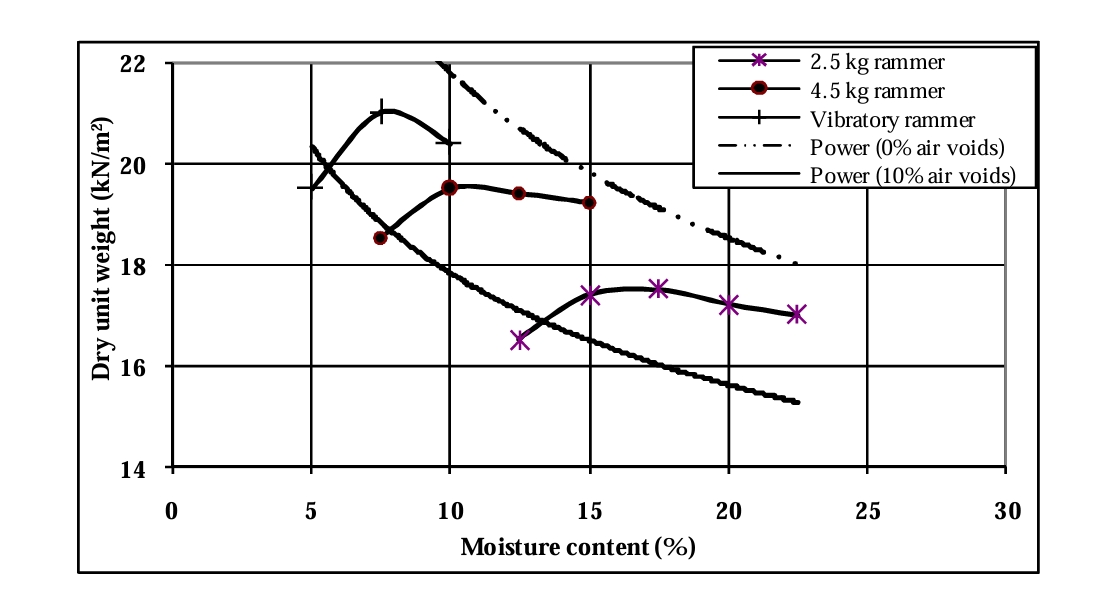

There are two main types of Proctor tests, each with distinct applications and compactive efforts:

| Test Type | Compactive Effort | Mold Volume | Hammer Weight | Drop Height | Typical Use Cases |

|---|---|---|---|---|---|

| Standard Proctor | Low | 0.95 L | 2.5 kg | 30.5 cm | Road subgrades, building pads |

| Modified Proctor | High (4x Standard) | 0.95 L | 4.5 kg | 45 cm | Airfields, highways, heavy loads |

Reference: ASTM D698 (Standard), ASTM D1557.

The Proctor Test Process: Step-by-Step (2.5kg Rammer)

1. Sample Collection and Preparation

Collect a representative soil sample from the construction site.

Air-dry and break down soil aggregates.

Remove organic matter and oversized particles.

- The test covers soil with particles finer than 20mm sieve size.

2. Sieve Analysis

Pass the soil through a 4.75 mm sieve to ensure uniformity.

Discard larger particles, as they can affect compaction results.

3. Determining Initial Moisture Content

Weigh a portion of the soil.

Oven-dry at 105–110°C for 24 hours.

Calculate moisture content using:

Moisture Content (%)=(Wet Weight−Dry Weight)/Dry Weight×100

4. Compaction Procedure

The mould for 2.5 kg rammer method is 1000 cm3 and 100mm diameter.

Divide soil into 3 (Standard) or 5 (Modified) equal layers.

The compaction is effected by free fall of

the 2.5 kg rammer through 300mm in three layers. Each layer receives 27 blowsFor each test, adjust the water content incrementally (typically 5 samples per test).

5. Measuring and Plotting Results

After compaction, trim and weigh the mold with soil.

Remove a sample for moisture content determination.

Calculate the dry density for each moisture content.

Plot a compaction curve (Dry Density vs. Moisture Content).

| Moisture Content (%) | Wet Density (g/cm³) | Dry Density (g/cm³) |

|---|---|---|

| 8 | 1.78 | 1.65 |

| 10 | 1.85 | 1.72 |

| 12 | 1.92 | 1.80 |

| 14 | 1.90 | 1.78 |

| 16 | 1.85 | 1.73 |

The peak of the curve indicates the Maximum Dry Density (MDD) and Optimum Moisture Content (OMC).

6. Interpreting Results

The OMC is the moisture content at which the soil achieves its MDD.

These values guide field compaction efforts to ensure the soil meets design specifications.

Field compaction is then verified by comparing in-situ densities to laboratory MDD values.

7. Quality Control and Field Application

Field density tests (e.g., sand cone, nuclear gauge) are conducted to ensure compaction meets or exceeds 95% of the laboratory MDD.

Specifications may require compaction within a certain range of the OMC (e.g., 75–105% of OMC).

Real-World Applications in Road Construction

Subgrade Preparation: Ensures a stable base for pavement layers.

Embankment Construction: Prevents settlement and slope failure.

Pavement Layers: Guides compaction of base and sub-base materials.

Related Questions

What is the difference between the Standard and Modified Proctor Test?

The Modified Proctor Test uses a heavier hammer and higher drop height, resulting in greater compactive effort. This simulates the effects of modern heavy machinery and is used for projects requiring higher density, such as highways and airfields.

Why is optimum moisture content critical?

If the soil is too dry, it won’t compact well; if too wet, water fills the voids, reducing density. The OMC ensures the best balance for maximum strength and stability.

Who sets the standards for Proctor Tests?

ASTM International: ASTM D698 (Standard), ASTM D1557 (Modified)

AASHTO: T99 (Standard), T180 (Modified)

Specification of the Field Compacted Density

The compacted density is usually specified as a percentage of the MDD as determined in the laboratory. In some instances the moisture content is required to be within a small band above or below the OMC. In rare instances the air content is specified. The specification usually ranges from 95-100% MDD when a 2.5 kg hammer is used the field control. A minimum number of roller passes is usually required to reach the desired compaction. The usual range is between 3 and 12 passes. In road work embankments the specification for the lower layers is usually a minimum of 95% MDD. The compaction for the upper subgrade and the pavement layers should

however be raised to between 100 and 105 MDD.

Real-World Applications in Road Construction

Subgrade Preparation: Ensures a stable base for pavement layers.

Embankment Construction: Prevents settlement and slope failure.

Pavement Layers: Guides compaction of base and sub-base materials.

Limitations of the Proctor Test

While the Proctor Test is widely used, it has some limitations that professionals must consider:

Sample Disturbance: The test uses remolded samples, which may not perfectly represent in-situ soil conditions.

Particle Size Restriction: Soils with large gravel or cobbles are not suitable for standard molds and require modified procedures.

Single Compactive Effort: The test does not account for varying field compaction energies or machinery types.

Not Suitable for All Soils: Highly organic soils, silts, or peat may not yield reliable results.

Related Questions

What is the difference between the Standard and Modified Proctor Test?

The Modified Proctor Test uses a heavier hammer and higher drop height, resulting in greater compactive effort. This simulates the effects of modern heavy machinery and is used for projects requiring higher density, such as highways and airfields.

Why is optimum moisture content critical?

If the soil is too dry, it won’t compact well; if too wet, water fills the voids, reducing density. The OMC ensures the best balance for maximum strength and stability.

Frequently Asked Questions

How is the Proctor Test used in pavement design?

Engineers use the test results to select subgrade and base materials, ensuring each layer meets density and moisture requirements for optimal pavement performance.

Can the Proctor Test be automated?

Some laboratories use automated compactors and digital data logging to increase accuracy and efficiency, but manual methods remain standard in most regions.

How does the Proctor Test compare to field compaction tests?

The Proctor Test provides a laboratory benchmark for maximum dry density and optimum moisture content. In the field, tests like the Sand Cone Method or Nuclear Density Gauge are used to check if the achieved compaction matches or exceeds the laboratory values. The field test results are expressed as a percentage of the laboratory MDD.

What are typical specifications for soil compaction in road projects?

Most road construction standards require:

95% or higher of laboratory MDD (from Proctor Test)

Moisture content within ±2% of OMC

Layer thickness: Compacted in lifts, typically 150–200 mm per layer

How do organizations use Proctor Test results in quality control?

Design: Engineers select suitable fill materials and compaction targets.

Construction: Contractors monitor moisture and density during compaction.

Inspection: Quality control teams verify compliance using field density tests.