Difference Between Rigid and Flexible Pavement

Difference Between Rigid and Flexible Pavement

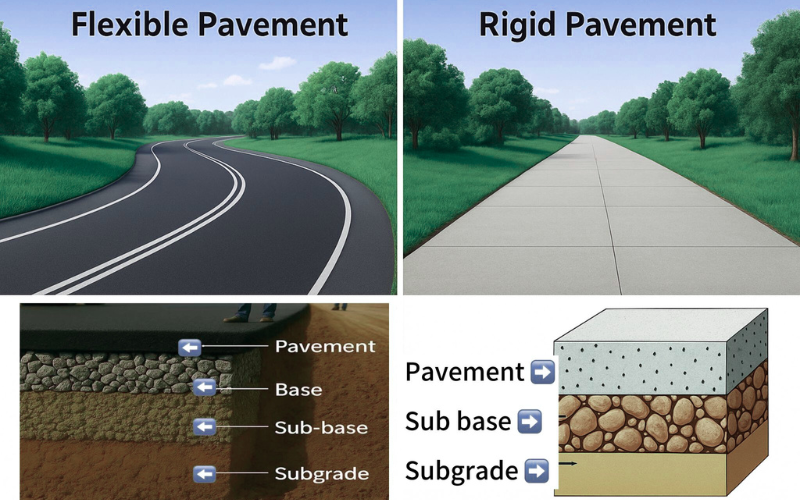

The difference between rigid and flexible pavement fundamentally affects road construction decisions in Kenya. Flexible pavement uses bituminous materials in multiple layers, distributing loads through grain-to-grain contact—offering lower initial costs and easier repairs but requiring frequent maintenance and lasting 10-15 years. Rigid pavement employs concrete slabs with high flexural strength, distributing loads through slab action—costing 50-100% more initially but lasting 30-40 years with minimal maintenance. Climate, traffic volumes, subgrade conditions, and budget constraints determine optimal selection for specific projects.

Ever driven on a smooth highway and wondered what makes it hold up under thousands of vehicles daily? The difference between rigid and flexible pavement determines whether a road lasts decades or requires constant patching. These two pavement types form the backbone of Kenya's transportation network, from Nairobi's bustling expressways to rural feeder roads connecting communities across the country.

Understanding these pavement systems isn't just academic knowledge. It impacts project budgets, maintenance schedules, and long-term infrastructure performance. Whether you're a civil engineering student at the University of Nairobi, a contractor planning your next project, or a construction professional working with the National Construction Authority, this guide breaks down everything you need to know.

The choice between rigid and flexible pavement affects construction costs, durability, and maintenance requirements. Kenya's diverse climate—from coastal humidity in Mombasa to highland conditions in Nairobi—adds another layer of complexity to pavement selection. Let's dig into what sets these two systems apart and when to use each one.

What is Flexible Pavement?

Flexible pavement is a multi-layered road structure that uses bituminous materials (asphalt) as the primary binding agent. Think of it as a layered cake where each layer plays a specific role in distributing vehicle loads down to the soil below. The term "flexible" describes how this pavement type bends and deflects under traffic loads without breaking—like a spring that compresses and rebounds.

The magic of flexible pavement lies in its grain-to-grain load transfer mechanism. When a heavy truck passes over the surface, the load doesn't stay concentrated in one spot. Instead, it spreads out progressively through each layer, reducing pressure as it travels downward. The top layer experiences maximum stress while lower layers handle progressively less.

Bituminous materials give flexible pavement its characteristic black appearance and slight give under pressure. These materials come from petroleum derivatives mixed with aggregates (crushed stone, sand, gravel) to create a durable wearing surface. The flexibility allows the pavement to accommodate minor movements in the underlying soil without cracking—crucial in areas with expansive soils or varying moisture content.

Most roads you see in Kenya use flexible pavement construction. From Thika Road to Mombasa Road, the dark asphalt surface indicates flexible pavement design. This popularity stems from lower initial costs and easier repair methods compared to rigid alternatives. However, this flexibility comes with trade-offs in longevity and maintenance frequency.

Related Question: Why is flexible pavement called "flexible"?

The name comes from its structural behavior under loads. Unlike rigid pavements that act as a stiff plate, flexible pavements actually bend (deflect) when vehicles pass over them. This bending is recoverable—the pavement springs back to its original shape after the load moves away. The bituminous binder provides this elastic property, allowing the pavement to flex without permanent deformation under normal traffic conditions.

Layers of Flexible Pavement

Flexible pavement typically consists of four distinct layers, each engineered for specific functions. Understanding these layers helps explain why flexible pavements require greater total thickness compared to rigid pavements.

Subgrade Layer

The subgrade forms the foundation—literally the natural soil beneath everything else. This layer must be properly compacted and graded before pavement construction begins. In Kenya, subgrade soils vary dramatically from region to region. Coastal areas often have sandy soils, while the Rift Valley features volcanic soils with different bearing capacities.

The subgrade's strength directly impacts pavement design. Engineers assess subgrade quality using the California Bearing Ratio (CBR) test, which measures soil strength and bearing capacity. Weak subgrades require thicker pavement layers to prevent excessive deflection and failure.

Subbase Layer

Sitting directly on the subgrade, the subbase provides additional load distribution and acts as a transition layer. This layer typically uses granular materials like gravel or crushed stone with better load-bearing characteristics than the subgrade soil. The subbase also provides drainage, preventing water accumulation that could weaken the pavement structure.

In Kenyan road construction, the subbase often incorporates locally available materials. The Kenya Road Design Manual 2025 specifies requirements for subbase materials, including gradation, strength properties, and compaction standards.

Base Course

The base course is the main structural layer, providing most of the pavement's load-bearing capacity. It consists of high-quality crushed stone or stabilized materials (soil mixed with cement or lime). This layer must be dense, well-compacted, and resistant to deformation under repeated traffic loads.

Material selection for the base course depends on expected traffic volumes and loads. High-traffic roads like highways require stronger base materials, often crushed stone meeting specific gradation requirements. Some projects use cement-stabilized materials for enhanced strength—a technique gaining popularity in Kenya's major road projects.

Surface Course (Wearing Course)

The surface course is what vehicles actually drive on—the visible layer made of asphalt concrete. This layer must be smooth, skid-resistant, and impermeable to water. It protects underlying layers from weather and traffic wear while providing a comfortable riding surface.

The surface course thickness varies based on traffic intensity. Urban highways might have 50-100mm of asphalt, while lighter rural roads use thinner layers. The construction practices, quality of materials, and proper mixing determines surface course performance and longevity.

Related Question: Can flexible pavement work without all four layers?

Technically, yes, but it's not recommended for permanent roads. Low-volume rural roads sometimes skip the subbase layer if the subgrade is strong enough. However, standard practice includes all four layers for proper load distribution and pavement longevity. Skipping layers saves initial costs but increases maintenance needs and reduces pavement life significantly.

What is Rigid Pavement?

Rigid pavement uses Portland Cement Concrete (PCC) as its primary structural element, creating a stiff, plate-like surface that distributes loads over a wide area. Unlike flexible pavement's layered approach, rigid pavement relies on the concrete slab's inherent strength—specifically its flexural strength or ability to resist bending.

Picture a concrete slab as a rigid plate floating on the ground. When a vehicle crosses it, the slab doesn't flex much. Instead, it acts like a beam, transferring the load across a broader area of the subgrade below. This slab action is rigid pavement's defining characteristic. The concrete's high strength allows it to span over weak spots in the subgrade without failing—engineers call this "bridging" capability.

The concrete slab typically measures 150-300mm thick, reinforced with steel bars to control cracking and increase strength. Unlike flexible pavement where each layer contributes to load-bearing, rigid pavement concentrates structural capacity in the concrete slab itself. This makes the concrete quality absolutely critical—poor concrete means pavement failure.

Rigid pavements appear lighter in color (gray or white) compared to flexible pavement's black asphalt. You'll see them at airports, industrial areas, and increasingly on Kenya's major highways where heavy truck traffic demands maximum durability. The Mombasa-Kwa Jomvu Highway features rigid pavement sections specifically designed for heavy port traffic.

Temperature changes pose rigid pavement's biggest challenge. Concrete expands in heat and contracts in cold, creating stress. That's why you see joints cut into concrete pavements—these allow controlled movement, preventing random cracking. Joint design and maintenance become crucial for rigid pavement longevity.

Related Question: Why use concrete instead of asphalt for rigid pavement?

Concrete provides superior flexural strength compared to asphalt, allowing thinner overall pavement structures for heavy loads. While asphalt distributes loads through layer-by-layer contact, concrete's beam-like behavior spreads loads more efficiently. This makes concrete ideal where heavy vehicles move slowly (like port access roads or climbing lanes) or where extremely long pavement life justifies higher initial costs. Additionally, cement availability in Kenya makes concrete a sustainable long-term choice.

Layers of Rigid Pavement

Rigid pavement structures are simpler than flexible pavements, typically consisting of two to three layers. This reduced layer count contributes to faster construction but concentrates more responsibility on concrete slab quality.

Subgrade

Just like flexible pavement, the subgrade provides the foundation. However, rigid pavement's bridging capability makes it somewhat less sensitive to subgrade variations. The concrete slab can span over localized weak spots without immediately failing—though severe subgrade problems will eventually cause issues.

Proper subgrade preparation remains essential. The Proctor compaction test ensures adequate density, while the CBR test verifies bearing capacity. In Kenya's varied terrain, subgrade conditions change dramatically even within a single project, requiring careful testing and preparation.

Base Course (Optional)

Many rigid pavements include a base course (also called subbase in some specifications), though it's not always required. When included, this layer typically uses lean concrete, cement-treated base, or dense graded aggregate. The base provides uniform support for the concrete slab and improves drainage.

The Kenya Road Design Manual sometimes specifies a granular base layer for rigid pavements, especially in areas with poor subgrade conditions. This base layer is thinner than flexible pavement bases since the concrete slab provides most structural capacity.

Concrete Slab (Surface Course)

The concrete slab is the star of the show—the primary structural element providing all load-bearing capacity. Pavement Quality Concrete (PQC) used in slabs must meet stringent requirements: minimum compressive strength of M40 grade (40 MPa or approximately 5,800 psi) and appropriate flexural strength.

Slab thickness depends on expected loads and subgrade strength. Highway slabs typically measure 200-300mm thick. The slab includes reinforcement—either distributed steel bars (reinforced concrete pavement) or steel mesh—to control cracking and hold cracks tightly together if they form.

Joints divide the concrete into manageable sections. Contraction joints control where cracks occur, expansion joints accommodate thermal movement, and construction joints separate pours. Joint spacing typically ranges from 3-5 meters, though continuously reinforced concrete pavement (CRCP) extends these distances significantly.

Related Question: Does rigid pavement need a subbase like flexible pavement?

Not always. Rigid pavement's high flexural rigidity allows it to bridge over subgrade irregularities more effectively than flexible pavement. Many rigid pavement designs place the concrete slab directly on prepared subgrade, especially when subgrade quality is adequate. However, a base course improves performance by providing uniform support, better drainage, and protection from subgrade pumping (fine particles being forced up through joints). The decision depends on project-specific conditions including traffic, climate, and subgrade characteristics.

How Do Flexible and Rigid Pavements Distribute Loads Differently?

The fundamental difference between these pavement types lies in load transfer mechanisms—how they spread vehicle weight down to the subgrade soil. This difference drives all other distinctions in design, performance, and applications.

Load Distribution in Flexible Pavement

Flexible pavement uses grain-to-grain contact to transfer loads. Imagine stacking marbles: each marble touches several others, distributing its weight among them. Similarly, when a truck tire presses on flexible pavement, the load transfers from aggregate particle to aggregate particle through each layer.

The top surface course receives concentrated stress directly under the tire. This stress spreads laterally as it moves down through the base course and subbase, with each layer distributing the load over a progressively wider area. By the time stress reaches the subgrade, it's spread over several square meters, reducing pressure to levels the soil can handle.

This progressive distribution explains why flexible pavements need multiple thick layers. Each layer must be strong enough to handle its stress level and spread loads to the layer below. The system works brilliantly but requires proper construction of all layers—weakness in any layer compromises the entire structure.

Load Distribution in Rigid Pavement

Rigid pavement operates completely differently, using slab action like a stiff beam or plate. When a wheel load hits the concrete slab, the slab bends slightly, but its high flexural strength prevents significant deflection. The load spreads across a large area of subgrade immediately—not through multiple layers, but through the slab's inherent rigidity.

Think of placing a heavy book on a wooden board laid across soft sand. The board (slab) distributes the book's weight across the entire board area, not just where the book sits. The sand (subgrade) under the whole board supports the load. This is slab action—the concrete's bending resistance spreads loads efficiently.

This mechanism allows rigid pavements to use fewer, thinner layers overall. The concrete slab provides structural capacity directly, with the base course (if present) mainly offering uniform support rather than load distribution. The slab can even bridge over small voids or weak spots in the subgrade without immediate failure—though such conditions eventually cause problems.

Related Question: Which load distribution method is better?

Neither is inherently "better"—each suits different conditions. Grain-to-grain transfer (flexible) works excellently for moderate loads and allows easy repairs by replacing damaged layers. It's cost-effective and adapts well to subgrade movements. Slab action (rigid) excels with very heavy loads or where long pavement life justifies higher costs. Rigid pavement's bridging ability handles subgrade weaknesses better, but repairs are more complex and expensive. The road networks choice depends on traffic, budget, climate, and maintenance capabilities —factors that vary across Kenya's diverse road network.

Key Structural Differences Between Rigid and Flexible Pavement

Beyond load distribution mechanisms, several structural characteristics distinguish these pavement types. These differences influence design decisions, construction processes, and long-term performance in Kenya’s diverse conditions.

Flexural Strength Requirements

Flexible pavement relies on relatively low flexural strength. The asphalt surface must resist cracking under bending, but the layer-by-layer load distribution means no single layer needs exceptional flexural capacity. The system’s strength comes from cumulative thickness—building up layers until combined resistance exceeds anticipated loads.

Rigid pavement demands high flexural strength—typically 40-45 kg/cm² (approximately 4-4.5 MPa) for pavement quality concrete. This strength allows the slab to act as a structural beam, spanning over weak subgrade spots without immediate failure. The concrete must resist bending stresses that would crack inferior materials.

Number and Thickness of Layers

Flexible pavements typically require four distinct layers with combined thickness often exceeding 500mm for heavy-traffic roads. Each layer contributes to load distribution, creating a thick structural system.

Rigid pavements use two to three layers with total thickness often under 400mm. The concrete slab provides most structural capacity, reducing the need for extensive underlying layers. This simpler structure speeds construction but demands higher-quality concrete work.

Material Composition

Flexible pavements combine bituminous binders (derived from petroleum) with aggregates. The binder provides flexibility and water resistance, while aggregates supply strength. Material availability affects costs significantly—Kenya imports bitumen, making prices vulnerable to global petroleum markets.

Rigid pavements use Portland cement concrete—cement, aggregates, water, and sometimes admixtures. Portland cement production in Kenya creates more price stability compared to imported bitumen. However, cement quality variations affect pavement performance, requiring careful material testing.

Temperature Behavior

Flexible pavements expand and contract with temperature changes but remain relatively stable. The bituminous binder softens in heat and stiffens in cold, allowing gradual accommodation of thermal changes without structural damage.

Rigid pavements experience significant thermal stresses. Concrete expands notably when heated and contracts when cooled. Without proper joints, these movements create destructive internal stresses leading to cracking. Kenya’s temperature variations—especially between day and night—make joint design critical for rigid pavement success.

Related Question: Why does rigid pavement need joints while flexible pavement doesn’t?

Concrete’s thermal expansion coefficient and inability to flex without cracking require expansion and contraction joints. These joints create controlled locations for movement, preventing random cracking throughout the slab. Flexible pavement’s bituminous binder accommodates thermal changes through its inherent flexibility—the material bends slightly rather than cracking. Additionally, flexible pavement layers can shift microscopically at interfaces, dissipating thermal stresses that would crack rigid materials.

Advantages of Flexible Pavement

Flexible pavement dominates Kenya’s road network for compelling reasons. Understanding these advantages helps explain why most highways, urban streets, and rural roads use asphalt surfaces despite requiring more frequent maintenance.

Lower Initial Construction Costs

Flexible pavement typically costs 30-50% less initially than rigid pavement for equivalent traffic capacity. Material costs favor asphalt, and construction equipment is more widely available. For Kenya’s extensive road network needs, this cost difference allows more kilometers of road construction within budget constraints.

The Kenya Roads Board data shows flexible pavement construction averaging significantly lower per-kilometer costs. This affordability makes flexible pavement practical for secondary and tertiary roads where traffic volumes don’t justify rigid pavement’s premium.

Easier and Faster Repairs

Damaged flexible pavement sections can be patched within hours. Contractors remove damaged asphalt, prepare the base if necessary, and overlay fresh asphalt. Traffic can resume almost immediately after compaction. This quick repair capability minimizes disruption—critical on busy routes like Nairobi’s Mombasa Road or Thika Superhighway.

Repairs don’t require specialized skills beyond standard road construction practices. Most Kenyan contractors possess equipment and expertise for asphalt work, making repairs accessible nationwide. This widespread capability supports Kenya’s decentralized road maintenance programs.

Shorter Construction Time

Asphalt cures quickly—surface courses can open to traffic within hours of placement. This rapid turnaround reduces traffic disruptions and accelerates project completion. For time-sensitive projects or phased construction, flexible pavement offers scheduling advantages.

Construction doesn’t require waiting for concrete to gain strength. Once compacted and cooled, asphalt develops usable strength immediately. This speed matters particularly for projects affecting commercial corridors where extended closures impose economic costs.

Better Adaptability to Subgrade Movement

Flexible pavement accommodates minor subgrade settlements without immediate structural failure. The layered system can deform slightly, distributing settlement effects across larger areas. While excessive settlement eventually causes problems, flexible pavement tolerates more subgrade variation than rigid alternatives.

Kenya’s expansive soils—particularly in Nairobi and surrounding areas—create challenging foundation conditions. Flexible pavement’s tolerance for movement makes it safer for sites where subgrade behavior uncertainty exists. The foundation types soil conditions vary significantly across different regions.

Recyclability

Modern asphalt is highly recyclable. Milled asphalt from old pavements can be reprocessed and incorporated into new mixes—some countries recycle nearly 100% of removed asphalt. This recyclability reduces material costs and environmental impact. As Kenya’s road network matures, asphalt recycling offers economic and sustainability benefits.

Related Question: Can flexible pavement be repaired without closing the entire road?

Yes, absolutely. One of flexible pavement’s greatest advantages is localized repair capability. Contractors can patch a pothole or replace a damaged lane section while adjacent lanes remain open to traffic. This surgical approach minimizes disruption compared to rigid pavement, where repair work often affects entire slabs or larger sections. For Kenya’s busy urban corridors, maintaining traffic flow during repairs justifies flexible pavement selection.

Disadvantages of Flexible Pavement

Despite its advantages, flexible pavement presents significant challenges that drive maintenance costs and limit lifespan, particularly under heavy traffic and adverse weather conditions common in Kenya.

Frequent Maintenance Requirements

Flexible pavement demands regular maintenance—pothole patching, crack sealing, and periodic overlay. Without consistent attention, small defects rapidly worsen. Kenya’s seasonal heavy rains accelerate deterioration when water penetrates pavement layers, weakening the structure.

Maintenance frequency increases with traffic volume. High-traffic routes require intervention every 1-2 years, consuming budgets that could otherwise fund new construction. The KeRRA projects in 2026 and annual maintenance programs demonstrate the ongoing commitment flexible pavement requires.

Shorter Service Life

Flexible pavements typically last 10-15 years before requiring major rehabilitation or reconstruction. Heavy trucks, especially when overloaded, accelerate this timeline. By comparison, properly constructed rigid pavements can serve 30-40 years, though initial costs are higher.

Kenya’s axle load challenges—heavy trucks often exceeding legal weight limits—particularly stress flexible pavements. The relatively thin asphalt layers deform under excessive loads, creating permanent rutting that compromises safety and comfort.

Vulnerability to Petroleum Products

Spilled fuel, oil, or other petroleum products dissolve bituminous binders, creating soft spots and potholes. Gas stations, truck stops, and industrial areas experience accelerated pavement damage from petroleum contamination. This vulnerability requires protective measures or alternative pavement types in high-risk locations.

Rutting and Deformation

Under heavy, slow-moving traffic—particularly at intersections, bus stops, or climbing sections—flexible pavement develops ruts (permanent deformation channels). These ruts collect water, accelerating damage and creating safety hazards. Kenya’s hilly terrain includes numerous climbing sections where loaded trucks stress pavements maximally.

Temperature Sensitivity

Extreme heat softens bituminous materials, reducing pavement stiffness and increasing deformation susceptibility. Kenya’s hot coastal regions and Rift Valley areas experience temperatures that challenge flexible pavement performance. Conversely, cold highland temperatures (though moderate by global standards) can make asphalt brittle and prone to cracking.

Related Question: Why do flexible pavements develop potholes so quickly in Kenya?

Multiple factors combine: inadequate drainage allows water infiltration that weakens base layers; heavy rainfall seasons create hydraulic pressures that break up pavement; overloaded trucks exceed design capacities; and delayed maintenance allows small cracks to expand rapidly. Additionally, some roads were built to lower standards with insufficient pavement thickness for current traffic volumes. Water is flexible pavement’s greatest enemy—once it penetrates the surface, repeated traffic loads pump water through layers, eroding materials and creating voids that collapse into potholes.

Advantages of Rigid Pavement

Rigid pavement offers compelling long-term benefits that justify higher initial investment for specific applications. Understanding these advantages helps identify where concrete pavements deliver superior value despite premium costs.

Exceptional Longevity

Properly designed and constructed rigid pavements last 30-40 years with minimal maintenance—often double or triple flexible pavement lifespan. This longevity stems from concrete’s durability and resistance to deformation. The Thika Road superhighway incorporates rigid pavement sections specifically designed for extended service life under heavy traffic.

Long life reduces lifecycle costs significantly. While initial construction costs more, avoiding frequent reconstruction saves money over decades. For high-traffic corridors where reconstruction disrupts commerce, longevity provides economic value beyond direct cost savings.

Superior Load-Carrying Capacity

Rigid pavement’s high flexural strength allows it to carry heavier loads than flexible pavement of equivalent thickness. The slab action distributes concentrated loads efficiently, preventing excessive stress on any single point. This capability makes rigid pavement ideal for port access roads, industrial areas, and freight corridors serving Kenya’s import-export economy.

Airports use rigid pavements almost exclusively for runways and taxiways. Aircraft impose extreme loads on small contact areas—only concrete provides sufficient strength without excessive thickness. Moi International Airport in Mombasa and Jomo Kenyatta International Airport feature extensive rigid pavement areas handling everything from small planes to heavy cargo aircraft.

Lower Long-Term Maintenance Costs

Beyond occasional joint sealing, rigid pavements require minimal routine maintenance. No annual pothole patching, no frequent resurfacing, no rut filling. Maintenance crews can focus resources elsewhere, improving overall network condition. This low-maintenance characteristic proves valuable for high-traffic routes where lane closures impose significant economic costs.

Better Fuel Economy

Studies show vehicles consume 15-20% less fuel on rigid pavements compared to flexible pavements. The hard, non-deforming surface reduces rolling resistance. For Kenya’s commercial transport sector—where fuel represents a major operating expense—this efficiency benefit accumulates into substantial savings. Though individual vehicle owners may not notice, fleet operators see measurable fuel cost reductions.

Resistance to Petroleum Products

Concrete doesn’t dissolve when exposed to spilled fuel or oil. This chemical resistance makes rigid pavement ideal for gas stations, truck terminals, and loading bays where petroleum exposure is inevitable. While fuel still requires cleanup for environmental reasons, the pavement structure remains intact.

Better Performance in Hot Weather

Unlike bituminous materials that soften in heat, concrete maintains strength at high temperatures. Kenya’s hot regions—particularly Garissa, Mandera, and coastal lowlands—challenge flexible pavement performance. Rigid pavement eliminates heat-related deformation, maintaining structural integrity year-round.

Related Question: Is rigid pavement more environmentally friendly than flexible pavement?

Generally, yes. Cement production locally in Kenya reduces import dependency compared to petroleum-derived bitumen. Concrete’s longer lifespan means fewer reconstruction cycles, reducing material consumption and construction-related emissions over decades. The fuel economy benefit further reduces carbon footprint—commercial vehicles driving millions of kilometers save substantial fuel. However, cement production itself generates CO2 emissions, so the comparison depends on project-specific factors and lifecycle analysis.

Disadvantages of Rigid Pavement

Despite impressive performance characteristics, rigid pavement presents challenges that limit its application in Kenya. These disadvantages explain why flexible pavement remains dominant despite rigid pavement’s superior longevity.

High Initial Construction Costs

Rigid pavement typically costs 50-100% more initially than flexible pavement for equivalent capacity. Material costs, specialized construction equipment, and skilled labor requirements all increase expenses. For developing countries like Kenya with extensive infrastructure needs but limited budgets, this cost premium restricts rigid pavement to high-priority corridors.

Construction equipment for concrete paving—slip-form pavers, concrete batching plants, specialized finishing equipment—represents significant capital investment. Many Kenyan contractors lack this equipment, limiting competitive bidding and potentially increasing project costs further.

Complex and Expensive Repairs

Damaged rigid pavement requires extensive repair work. Unlike flexible pavement where contractors patch specific spots, concrete repairs often involve removing and replacing entire slabs. The repair must cure for days before traffic can resume—creating extended disruptions.

Matching new concrete to existing slabs challenges even skilled contractors. Color, texture, and elevation mismatches create obvious patches that never quite disappear. For aesthetic considerations on urban boulevards or approaches to key facilities, this permanent visible repair evidence proves undesirable.

Joint Maintenance Requirements

Expansion and contraction joints demand regular maintenance. Joint sealants deteriorate, allowing water and debris infiltration. Foreign objects lodged in joints cause spalling (concrete breaking away from edges) under traffic loads. While less frequent than flexible pavement maintenance, joint work requires specialized materials and skills.

Neglected joints cause premature pavement failure. Water infiltrating through joints washes away base material, creating voids. The unsupported slab then cracks under traffic—potentially requiring complete slab replacement rather than simple joint resealing.

Longer Construction Time

Concrete requires 7-28 days to develop design strength before opening to traffic. This curing period complicates project scheduling and extends traffic disruptions. For projects on busy corridors, the extended closure period imposes economic costs that can outweigh pavement performance benefits.

Phased construction becomes more complex with rigid pavement. Each phase must cure fully before proceeding, whereas flexible pavement allows rapid sequential construction. Time-critical projects often choose flexible pavement purely for scheduling advantages.

Rough Riding Quality

Despite smooth construction, rigid pavement joints create slight discontinuities felt as rhythmic bumps when driving. This characteristic “thump-thump” can become annoying, particularly at highway speeds. Modern continuously reinforced concrete pavement (CRCP) minimizes this effect but increases costs further.

Joint noise also concerns residents near rigid pavement roads. The tire noise at joints carries farther than smooth asphalt, potentially affecting property values in residential areas.

Poor Suitability for Expansive Soils

Kenya’s expansive soils—particularly black cotton soil around Nairobi—pose challenges for rigid pavement. Soil expansion and contraction create uneven support, inducing slab warping and cracking. While properly designed base layers can mitigate this, the added complexity and cost reduce rigid pavement’s attractiveness in expansive soil regions. Thorough geotechnical investigation becomes even more critical for rigid pavement projects.

Related Question: Can rigid pavement crack despite its high strength?

Yes. Even high-strength concrete cracks under certain conditions: thermal stresses from temperature variations; subgrade settlement creating uneven support; inadequate joint spacing forcing cracks between intended joints; heavy overloads exceeding design capacity; or chemical reactions like alkali-silica reaction (ASR) that expand within concrete. That’s why joint design, proper construction practices, quality materials, and adequate base support all matter critically. Well-designed rigid pavement controls where cracks occur (at joints) rather than preventing cracking entirely.

Cost Comparison in Kenya

Choosing between rigid and flexible pavement requires comprehensive cost analysis over the pavement’s entire lifecycle, not just initial construction. Kenya’s diverse regional conditions create significant cost variations.

Initial Construction Costs

Based on Kenya Roads Board data and recent projects, flexible pavement costs approximately Ksh 26-90 million per kilometer for various road classifications. Superhighways and international trunk roads cost most; secondary roads cost least. Regional variations reflect material transport costs—coastal and western regions often pay premiums compared to Nairobi area.

Rigid pavement construction typically costs Ksh 50-150 million per kilometer—roughly 50-100% more than comparable flexible pavement. The higher cost reflects concrete material expenses, specialized equipment, and longer construction timelines.

Maintenance Costs Over Time

Flexible pavement requires annual maintenance averaging 2-5% of initial construction cost, plus major rehabilitation every 10-15 years costing 40-60% of original construction. Accumulated over 30 years, maintenance costs can equal or exceed initial construction expenses.

Rigid pavement maintenance averages under 1% annually—mainly joint sealing and minor repairs. Even after 30 years, total maintenance costs typically remain under 15% of initial construction. This dramatic difference creates crossover points where rigid pavement becomes economical despite higher upfront costs.

Long-Term Value Analysis

For low-traffic rural roads (under 500 vehicles daily), flexible pavement usually delivers better value. Low traffic imposes minimal wear, extending flexible pavement life while rigid pavement’s longevity advantage remains underutilized. Initial cost savings allow construction of more road kilometers.

For high-traffic urban corridors (over 5,000 vehicles daily, particularly with heavy trucks), rigid pavement often proves more economical over 30+ years. The longer service life, lower maintenance costs, and reduced traffic disruption provide value exceeding the initial premium.

Medium-traffic situations require project-specific analysis. Local material availability, contractor capabilities, subgrade conditions, and maintenance capacity all influence the optimal choice.

Regional Cost Variations

Construction costs vary significantly across Kenya. Nairobi and Mt. Kenya regions benefit from proximity to cement manufacturing plants and better contractor availability, potentially favoring rigid pavement economically. Coastal regions face higher cement transport costs but also high bitumen costs—creating regional cost analysis complexity.

Western and Nyanza regions traditionally favor flexible pavement due to established asphalt plant networks and contractor familiarity. However, as the road network develops, rigid pavement may gain economic viability even in these regions.

Related Question: Why doesn’t Kenya use more rigid pavement if it lasts longer?

Budget constraints represent the primary reason. Kenya needs thousands of kilometers of improved roads—spending double the amount per kilometer halves the network kilometers achievable with available funding. Additionally, maintenance funding often comes from different budget sources than construction, making initial capital costs the binding constraint. Many decision-makers prioritize network coverage over pavement longevity, particularly for rural connectivity. Finally, contractor capacity limitations and construction time considerations favor familiar flexible pavement technology.

Applications: When to Use Each Type in Kenya

Selecting appropriate pavement type requires matching pavement characteristics to site conditions, traffic patterns, and project objectives. Here’s guidance for Kenyan construction professionals:

When to Use Flexible Pavement

Rural and secondary roads with traffic volumes under 1,000 vehicles daily benefit from flexible pavement’s lower cost. These roads need improvement but don’t justify rigid pavement’s premium. Quick construction and repair accessibility matter more than maximum longevity.

Residential streets in urban developments suit flexible pavement. Lower traffic volumes, shorter travel distances, and aesthetic preferences for dark asphalt support this choice. Easier utility access for water, sewer, and electricity connections adds practical advantages.

Temporary or staged projects where future widening or realignment is anticipated should use flexible pavement. The ability to remove and recycle asphalt makes future modifications more economical than breaking up concrete slabs.

Projects with budget constraints often default to flexible pavement. When funding limits total investment, building more kilometers of flexible pavement serves more people than fewer kilometers of rigid pavement.

Areas with uncertain subgrade conditions where comprehensive geotechnical investigation wasn’t possible benefit from flexible pavement’s tolerance for minor settlements. While proper investigation remains ideal, practical constraints sometimes force working with uncertainty.

When to Use Rigid Pavement

Port access roads and freight corridors handling heavy truck traffic justify rigid pavement investment. The ability to carry extreme loads without deformation, combined with low maintenance needs, provides long-term value. The Mombasa Port access routes exemplify this application—heavy trucks moving slowly impose maximum pavement stress.

Airport pavements—runways, taxiways, aprons—require rigid pavement’s load capacity and fuel resistance. Aircraft impose concentrated loads exceeding highway truck weights, and jet fuel spills would destroy asphalt surfaces. Both Jomo Kenyatta International Airport and Moi International Airport rely extensively on concrete pavements.

Industrial areas with heavy equipment and slow-moving loads benefit from rigid pavement. Manufacturing facilities, logistics parks, and heavy industrial zones generate traffic patterns particularly damaging to flexible pavement. Concrete eliminates rutting and deformation concerns.

High-speed highways where smooth riding surface and low rolling resistance matter economically favor rigid pavement. Superhighways carrying high traffic volumes benefit from fuel economy improvements and reduced maintenance disruptions. Though initial costs increase, lifecycle economics and service quality justify investment.

Intersections and climbing sections on otherwise flexible pavements often use rigid pavement for critical zones. Heavy trucks slow at intersections and exert maximum stress climbing hills—both conditions accelerate flexible pavement failure. Strategic rigid pavement placement extends overall pavement life.

Weighbridge areas must use rigid pavement. Trucks stopping frequently and moving slowly over the same location would destroy flexible pavement rapidly. The concentrated, repetitive loading requires concrete’s resistance to deformation.

Case Study: Mombasa-Kwa Jomvu Highway

Recent Kenya National Highways Authority (KeNHA) projects illustrate strategic pavement selection. The Mombasa-Kwa Jomvu Highway serves extremely heavy truck traffic accessing Mombasa Port. KeNHA specified rigid pavement for this corridor recognizing that:

- Truck volumes exceed 5,000 daily with many overloaded vehicles

- Slow-moving heavy vehicles climbing grades impose maximum pavement stress

- Maintenance disruptions impose high economic costs due to commercial importance

- Hot coastal climate challenges flexible pavement performance

- Long-term economics favor durability despite higher initial investment

Related Question: Can you mix rigid and flexible pavement on the same road?

Yes—composite pavement strategically combines both types. Common applications include rigid pavement at intersections, bus stops, or climbing sections where stress concentrates, with flexible pavement on remaining sections. Another approach overlays flexible pavement onto deteriorated rigid pavement, combining rigid base strength with flexible surface characteristics. However, the transition zones between pavement types require careful design to avoid failures at the interfaces where different materials meet.

Performance in Kenyan Climate Conditions

Kenya’s climate varies dramatically from humid coastal regions to arid northern areas to cool highlands. These conditions significantly impact pavement performance and selection.

Impact of Rainfall

Kenya’s bimodal rainfall pattern—long rains March-May and short rains October-December—creates challenging conditions for pavements. Heavy rainfall tests drainage systems and accelerates pavement deterioration when water infiltrates through cracks.

Flexible pavement suffers particularly from inadequate drainage. Water trapped in base layers reduces load-bearing capacity and creates pumping action under traffic that breaks up pavement structure. Coastal regions with high annual rainfall require especially robust drainage design.

Rigid pavement handles rainfall better structurally but faces joint sealing challenges. Water entering through deteriorated joints washes out base material, creating voids under slabs. Pumping of fine materials through joints manifests as staining and concrete spalling.

Temperature Variations

Coastal regions (Mombasa, Kilifi, Lamu) experience high temperatures with minimal daily variation—averaging 25-30°C year-round. These conditions challenge flexible pavement by softening bituminous binders, though extreme temperature swings don’t occur.

Highland regions (Nairobi, Nakuru, Nyeri) feature moderate temperatures—typically 15-25°C—with significant day-night variations. Morning temperatures may dip below 10°C while afternoons reach 25°C. These cycles create thermal stresses, particularly for rigid pavement where daily expansion-contraction cycles stress joints.

Arid northern regions (Garissa, Mandera) experience extreme heat—often exceeding 35°C—that severely challenges flexible pavement. Bitumen softens substantially, increasing deformation risk. Rigid pavement performs better but faces increased thermal stress from extreme temperature ranges.

Soil Moisture Content Variations

Kenya’s expansive black cotton soils around Nairobi and other highland areas expand when wet and shrink when dry. These volume changes create uneven pavement support that stresses both pavement types but particularly challenges rigid pavement. The soil compaction becomes absolutely critical in these areas.

Seasonal moisture variations require pavement designs accounting for worst-case wet conditions. Subgrade bearing capacity can drop dramatically during rainy seasons, requiring adequate pavement thickness to prevent excessive deflection even when subgrade is weakest.

Related Question: Does Kenya’s equatorial climate favor one pavement type over the other?

Not definitively—different climate aspects favor each type. High temperatures in lowland areas challenge flexible pavement but don’t significantly affect rigid pavement. Seasonal rainfall creates drainage challenges for both types but particularly affects flexible pavement. Temperature stability (lack of freeze-thaw cycles) benefits both types compared to temperate climates. Overall, Kenya’s climate proves reasonably favorable for both pavement types compared to harsh continental climates with freeze-thaw cycles. Selection depends more on traffic, economics, and specific site conditions than climate alone.

Order Construction Materials From Us Today

Box Profile (Glossy, Gauge 28)

KSh 650.00

Our Box Profile iron sheets are crafted for superior durability and exceptional weather resistance, making them the ideal choice for long-lasting roofing solutions across Kenya. To make your project even more convenient, we offer free delivery across Kenya when one orders 40 pieces and above. Trust us for reliable products and dependable service for all your building needs.

Box Profile (Glossy)

KSh 470.00

Our Box Profile iron sheets are crafted for superior durability and exceptional weather resistance, making them the ideal choice for long-lasting roofing solutions across Kenya. To make your project even more convenient, we offer free delivery across Kenya when one orders 40 pieces and above. Trust us for reliable products and dependable service for all your building needs.

Box Profile (Matte, Gauge 28)

KSh 680.00

Our Box Profile iron sheets are crafted for superior durability and exceptional weather resistance, making them the ideal choice for long-lasting roofing solutions across Kenya. To make your project even more convenient, we offer free delivery across Kenya when one orders 40 pieces and above. Trust us for reliable products and dependable service for all your building needs.

Box Profile (Matte)

KSh 530.00

Our Box Profile iron sheets are crafted for superior durability and exceptional weather resistance, making them the ideal choice for long-lasting roofing solutions across Kenya. To make your project even more convenient, we offer free delivery across Kenya when one orders 40 pieces and above. Trust us for reliable products and dependable service for all your building needs.

Corrugated Iron Sheet (Gauge 30)

KSh 470.00

Our corrugated iron sheets are crafted for superior durability and exceptional weather resistance, making them the ideal choice for long-lasting roofing solutions across Kenya. To make your project even more convenient, we offer free delivery across Kenya when one orders 40 pieces and above. Each high-quality sheet provides excellent value for money, ensuring your structure is protected for years to come. Trust us for reliable products and dependable service for all your building needs.

Elegantile (Glossy, Gauge 28)

KSh 670.00

Our Elegant Tile profile are crafted for superior durability and exceptional weather resistance, making them the ideal choice for long-lasting roofing solutions across Kenya. To make your project even more convenient, we offer free delivery across Kenya when one orders 40 pieces and above. Trust us for reliable products and dependable service for all your building needs.

Elegantile (Glossy, Gauge 30)

KSh 550.00

Our Elegant Tile profile are crafted for superior durability and exceptional weather resistance, making them the ideal choice for long-lasting roofing solutions across Kenya. To make your project even more convenient, we offer free delivery across Kenya when one orders 40 pieces and above. Trust us for reliable products and dependable service for all your building needs.

Elegantile (Matte, Gauge 28)

KSh 680.00

Our Elegant Tile profile with matte texture are crafted for superior durability and exceptional weather resistance, making them the ideal choice for long-lasting roofing solutions across Kenya. To make your project even more convenient, we offer free delivery across Kenya when one orders 40 pieces and above. Trust us for reliable products and dependable service for all your building needs.

Elegantile (Matte, Gauge 30)

KSh 580.00

Our Elegant Tile profile with matte texture are crafted for superior durability and exceptional weather resistance, making them the ideal choice for long-lasting roofing solutions across Kenya. To make your project even more convenient, we offer free delivery across Kenya when one orders 40 pieces and above. Trust us for reliable products and dependable service for all your building needs.

Versatile (Glossy, Gauge 28)

KSh 670.00

Our versatile iron sheets are crafted for superior durability and exceptional weather resistance, making them the ideal choice for long-lasting roofing solutions across Kenya. To make your project even more convenient, we offer free delivery across Kenya when one orders 40 pieces and above. Trust us for reliable products and dependable service for all your building needs.

Versatile (Glossy, Gauge 30)

KSh 550.00

Our versatile iron sheets are crafted for superior durability and exceptional weather resistance, making them the ideal choice for long-lasting roofing solutions across Kenya. To make your project even more convenient, we offer free delivery across Kenya when one orders 40 pieces and above. Trust us for reliable products and dependable service for all your building needs.

Versatile (Matte, Gauge 28)

KSh 680.00

Our versatile iron sheets are crafted for superior durability and exceptional weather resistance, making them the ideal choice for long-lasting roofing solutions across Kenya. To make your project even more convenient, we offer free delivery across Kenya when one orders 40 pieces and above. Trust us for reliable products and dependable service for all your building needs.

Frequently Asked Questions

Which type of pavement lasts longer?

Rigid pavement lasts significantly longer—typically 30-40 years compared to 10-15 years for flexible pavement. Concrete's durability and resistance to deformation provide extended service life. However, this longevity advantage comes with 50-100% higher initial construction costs. For high-traffic applications where maintenance disruptions impose economic costs, rigid pavement's longevity justifies the premium. For lower-traffic routes, flexible pavement's lower initial cost outweighs shorter service life.

What is the main difference between rigid and flexible pavement?

The fundamental difference lies in load transfer mechanisms. Flexible pavement uses grain-to-grain contact through multiple layers to progressively distribute loads to the subgrade. Rigid pavement uses slab action—the concrete's flexural strength allows it to act as a beam, distributing loads across wide areas immediately. This difference drives all other distinctions: flexible uses multiple thick layers while rigid uses fewer thinner layers; flexible accommodates movement while rigid resists it; flexible requires frequent maintenance while rigid needs minimal attention.

Why is flexible pavement more common in Kenya?

Lower initial costs represent the primary reason—flexible pavement costs 30-50% less than rigid pavement initially. With extensive road network needs but limited infrastructure budgets, Kenya prioritizes network coverage over pavement longevity. Additionally, contractors and road agencies possess more experience and equipment for asphalt construction. Material availability also matters—bitumen plants exist throughout Kenya, while specialized concrete paving equipment remains less common. Finally, quick construction timelines and easier repairs suit Kenya's immediate infrastructure needs.

Can you use both pavement types on the same road?

Yes—composite pavements strategically combine both types. Common applications include rigid pavement at high-stress locations (intersections, climbing sections, bus stops) with flexible pavement elsewhere. Another composite approach places flexible overlay on rigid base, combining rigid pavement's structural capacity with flexible pavement's smooth riding characteristics and easier maintenance. However, transition zones between pavement types require careful design to prevent interface failures. The materials expand differently, support loads differently, and behave differently under traffic—making transitions potential weak points.

How does weather affect pavement choice in Kenya?

Temperature extremes favor rigid pavement—coastal heat challenges flexible pavement by softening bitumen, while concrete maintains strength. Heavy rainfall challenges both types but particularly affects flexible pavement when water infiltrates layers. Expansive soils activated by moisture variations create challenges for rigid pavement's slab action. Kenya's generally stable climate (no freeze-thaw cycles) suits both types reasonably well. Specific site conditions—coastal heat, highland expansive soils, northern aridity—influence which type performs better locally. Overall, climate considerations matter less than traffic volumes and budget constraints for most Kenyan projects.

What is semi-rigid pavement?

Semi-rigid pavement represents an intermediate category combining characteristics of both types. Typically, it uses cement-treated base layers under flexible asphalt surface courses. The cement stabilization provides rigidity and load-bearing capacity approaching rigid pavement, while the flexible surface maintains easier repairs and comfortable riding characteristics. Semi-rigid pavement costs more than purely flexible but less than rigid pavement, offering a middle-ground option. Kenya increasingly uses cement-stabilized bases for high-traffic routes where purely flexible pavement proves inadequate but rigid pavement costs exceed budgets.

Which pavement type is better for heavy truck traffic?

Rigid pavement handles heavy trucks better due to superior load-carrying capacity and deformation resistance. The concrete slab distributes heavy concentrated loads efficiently without permanent deformation. Slow-moving heavy vehicles—particularly problematic at intersections, climbing sections, and weighbridges—impose maximum stress that destroys flexible pavement through rutting. Rigid pavement eliminates these issues. However, properly designed flexible pavement with thick layers can accommodate moderate truck traffic economically. The decision depends on truck volume, weight patterns, and long-term economic analysis.

How much does it cost to build a road in Kenya?

Road construction costs vary dramatically based on classification and location. Recent projects range from Ksh 26 million to Ksh 900 million per kilometer. Secondary rural roads cost least (Ksh 26-60 million/km), urban roads and national highways cost more (Ksh 70-150 million/km), and superhighways cost most (over Ksh 200 million/km). Pavement type significantly impacts costs—rigid pavement adds 50-100% to costs compared to flexible pavement. Regional variations also matter—remote areas face higher material transport costs. For accurate project estimates, consult with registered quantity surveyors and consider site-specific conditions including terrain, drainage requirements, and existing infrastructure.