BS EN 1992 (Eurocode 2): The Definitive Guide to Concrete Structure Design (PDF)

BS EN 1992 (Eurocode 2): Guide to Concrete Structure Design

This comprehensive guide explores BS EN 1992 (Eurocode 2), covering fundamental design principles, material specifications, and practical applications for Kenya’s construction industry. The article details Kenya’s transition from British Standards, explains limit state design philosophy, and provides insights into designing reinforced concrete elements including beams, slabs, and columns. Essential reading for structural engineers, architects, and construction professionals adapting to current design codes.

BS EN 1992 (Eurocode 2) has revolutionized how Kenya's construction industry approaches concrete structure design. Since the country's shift from British Standards in 2021, understanding this comprehensive design code has become essential for every structural engineer, architect, and construction professional working in Kenya. This transition marks a significant milestone in aligning Kenya's construction practices with international standards while maintaining structural safety and quality.

The adoption of Eurocode 2 represents more than just a change in design codes. It fundamentally reshapes how we calculate, detail, and construct concrete structures across Kenya. Whether you're designing a residential building in Nairobi or planning infrastructure projects in Mombasa, EN 1992 provides the framework for safe, economical, and durable concrete design.

What is BS EN 1992 (Eurocode 2)?

BS EN 1992, commonly called Eurocode 2, is the European standard for designing concrete structures. It applies to buildings and civil engineering works constructed using plain concrete, reinforced concrete, and prestressed concrete. The "BS" prefix indicates the British Standards version, which Kenya adopted alongside other Commonwealth nations.

The code was developed by the European Committee for Standardization (CEN) through Technical Committee 250. It establishes principles and requirements for the safety and serviceability of concrete structures, providing comprehensive guidance on design methodology, material specifications, and construction detailing.

Unlike its predecessor British Standards, Eurocode 2 uses a limit state design philosophy that considers both ultimate and serviceability conditions. This approach ensures structures can withstand expected loads throughout their design life while maintaining functionality and appearance. The code emphasizes performance-based design rather than prescriptive rules, giving engineers greater flexibility while maintaining rigorous safety standards.

Kenya's National Construction Authority (NCA) officially mandated the transition to Eurocodes, working closely with the Kenya Bureau of Standards (KEBS) to facilitate adoption across the construction sector.

Why Does Eurocode 2 Matter?

For structural engineers in Kenya, EN 1992 offers several advantages. It harmonizes design standards internationally, making it easier to collaborate on projects with European consultants. The code incorporates decades of research and practical experience, providing more refined design methods than older British Standards. Most importantly, it addresses modern construction challenges including sustainability, durability, and performance under extreme conditions.

Understanding the Structure of EN 1992

Eurocode 2 consists of four main parts, each addressing specific aspects of concrete design. Understanding this structure helps you navigate the code efficiently and apply the correct provisions to your projects.

EN 1992-1-1: General Rules and Rules for Buildings

This fundamental section covers general design rules applicable to buildings. It contains provisions for material properties, structural analysis, ultimate limit states, serviceability limit states, and detailing requirements. Most building projects in Kenya rely primarily on this part.

The section specifies how to determine design strengths for concrete and reinforcement, calculate load effects, and verify structural adequacy. It provides detailed guidance on designing beams, slabs, columns, walls, and foundations. The code addresses both in-situ and precast concrete construction.

For Kenyan engineers, Part 1-1 serves as the daily reference for routine building design. It covers everything from determining concrete cover for durability to calculating deflections and crack widths. The section includes extensive tables, charts, and formulas that simplify complex calculations.

EN 1992-1-2: Structural Fire Design

Fire safety has become increasingly important in Kenya's high-rise construction boom. This part provides methods for designing concrete structures to resist fire. It specifies fire resistance ratings, thermal properties of concrete, and simplified calculation methods.

The code presents three approaches: tabular data method, simplified calculation method, and advanced calculation method. For most projects, the tabular method suffices, providing minimum dimensions and axis distances for specified fire resistance periods.

Kenyan building regulations require specific fire resistance periods based on building height and occupancy. EN 1992-1-2 helps engineers meet these requirements while optimizing member sizes and reinforcement arrangements.

EN 1992-2: Concrete Bridges

Bridge design requires specialized provisions addressing dynamic loads, fatigue, and long-term durability. This part extends the general rules to bridge structures, including additional checks for traffic loads, prestressing effects, and bridge-specific detailing.

Kenya's infrastructure development has seen numerous bridge projects where these provisions apply. The section addresses both highway and railway bridges, considering local conditions and load patterns.

EN 1992-3: Liquid Retaining and Containment Structures

Water tanks, swimming pools, and silos require specialized design to prevent leakage and ensure containment. This part provides crack width limitations, joint design, and special detailing requirements for structures holding liquids or granular materials.

Given Kenya's water storage infrastructure needs, these provisions guide engineers in designing durable, leak-free structures. The section emphasizes serviceability requirements more stringently than standard building design.

EN 1992-4: Design of Fastenings for Use in Concrete

This recent addition covers post-installed anchors, cast-in-place anchors, and mechanical fasteners. It provides design methods for tension, shear, and combined loading conditions.

The provisions apply to facade connections, equipment mounting, and structural modifications. As retrofit and renovation projects increase in Kenya, understanding these provisions becomes essential.

What are the main differences between EN 1992 parts? Each part addresses specific structure types or design aspects. Part 1-1 covers general buildings, while Parts 2, 3, and 4 provide specialized rules for bridges, liquid-retaining structures, and fastenings respectively. However, all parts reference the fundamental principles established in Part 1-1.

Kenya's Transition from British Standards to Eurocodes

Kenya officially began transitioning from British Standards (BS 8110 and CP65) to Eurocodes in 2021. This shift aligned Kenya with international best practices while maintaining technical rigor in structural design.

The Timeline and Implementation Process

The Kenya Bureau of Standards (KEBS) spearheaded the adoption process, working with academic institutions like Moi University's Department of Civil and Structural Engineering. They conducted training programs, workshops, and awareness campaigns to prepare the industry.

By January 2021, the transition became mandatory for all new projects. Existing projects under British Standards could continue, but new designs required Eurocode compliance. This phased approach minimized disruption while ensuring thorough preparation.

The implementation faced challenges. Many practicing engineers had decades of experience with British Standards but limited exposure to Eurocodes. Material suppliers needed to adjust specifications. Software developers updated design programs. The entire construction ecosystem adapted simultaneously.

Why Did Kenya Make This Change?

Several factors drove the transition. First, British Standards were becoming outdated, with limited updates after the UK adopted Eurocodes. Second, Kenya's regional integration efforts aligned with using internationally recognized standards. Third, Eurocodes offered more sophisticated design methods reflecting current research.

The East African Community encouraged harmonization of technical standards across member states. Adopting Eurocodes positioned Kenya at the forefront of this regional standardization effort.

When exactly did Kenya adopt Eurocode 2? The official adoption occurred in 2021, though preparatory work began years earlier. KEBS published the Kenyan versions of Eurocodes, incorporating National Annexes where necessary to address local conditions.

Impact on Engineering Practice

The transition required significant re-training. Universities updated curricula to teach Eurocode-based design. Professional development programs helped practicing engineers understand the new provisions. The National Construction Authority established competency requirements ensuring engineers possessed adequate Eurocode knowledge before practicing.

Design software companies released Eurocode-compliant versions of popular programs. This technological support eased the transition, though engineers still needed to understand underlying principles rather than blindly trusting software outputs.

Material specifications changed. Concrete is now designated using European strength classes (e.g., C25/30) rather than British grades. Reinforcement specifications adopted European standards. Local manufacturers adjusted production to meet new requirements.

Buy From Us Today

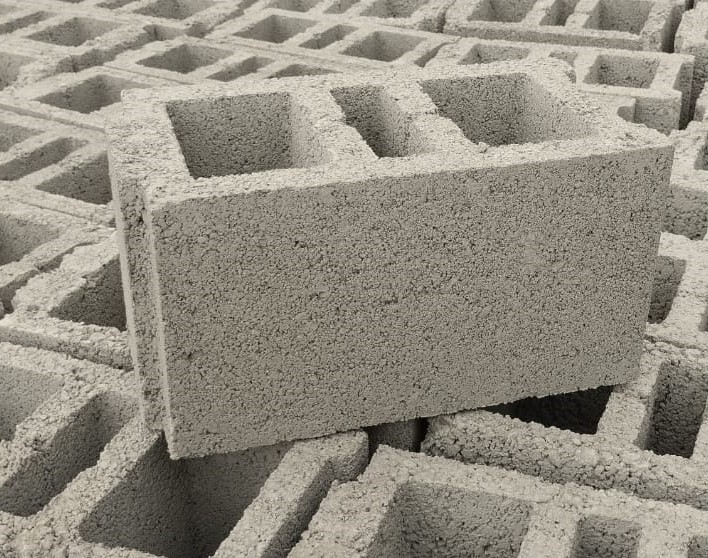

Hollow Concrete Blocks (380 by 150 by 200)

KSh 65.00

Premium hollow concrete blocks, engineered for superior strength and durability. Their exceptional quality ensures reliable performance for any construction project.

- Dimensions: 380mm (L) x 150mm (W) x 200mm (H)

- Lightweight: Easy to handle at just 8.4 kg per unit

- Coverage: Requires only 11.5 blocks per square meter

Ideal for efficient, high-quality wall construction.

WE OFFER FREE DELIVERY WITHIN NAIROBI

Hollow Concrete Blocks (380 by 190 by 100)

KSh 60.00

Premium hollow concrete blocks, engineered for superior strength and durability. Their exceptional quality ensures reliable performance for any construction project.

- Dimensions: 380mm (L) x 190mm (W) x 100mm (H)

- Lightweight: Easy to handle at just 6 kg per unit

- Coverage: Requires only 12 blocks per square meter

Ideal for efficient, high-quality wall construction.

WE OFFER FREE DELIVERY WITHIN NAIROBI

Hollow Concrete Blocks (380 by 200 by 200)

KSh 75.00

Premium hollow concrete blocks, engineered for superior strength and durability. Their exceptional quality ensures reliable performance for any construction project.

- Dimensions: 380mm (L) x 200mm (W) x 200mm (H)

- Lightweight: Easy to handle at just 9.4 kg per unit

- Coverage: Requires only 11.5 blocks per square meter

Ideal for efficient, high-quality wall construction.

WE OFFER FREE DELIVERY WITHIN NAIROBI

Hollow Pots (380 by 200 by 160)

KSh 70.00

Hollow Pots

Premium hollow pots, engineered for superior strength and durability. Their exceptional quality ensures reliable performance for any slab construction project. - Dimensions: 380mm (L) x 200mm (W) x 160mm (H) - Lightweight: Easy to handle at just 9.5 kg per unit - Coverage: Requires only 14 blocks per square meter Ideal for efficient, high-quality slab construction.WE OFFER FREE DELIVERY WITHIN NAIROBI

Hollow Pots (380 by 200 by 200)

KSh 85.00

Hollow Pots

Premium hollow pots, engineered for superior strength and durability. Their exceptional quality ensures reliable performance for any slab construction project. - Dimensions: 380mm (L) x 200mm (W) x 200mm (H) - Lightweight: Easy to handle at just 9.8 kg per unit - Coverage: Requires only 14 blocks per square meter Ideal for efficient, high-quality slab construction.WE OFFER FREE DELIVERY WITHIN NAIROBI

Hollow Pots (380 by 200 by 230)

KSh 90.00

Hollow Pots

Premium hollow pots, engineered for superior strength and durability. Their exceptional quality ensures reliable performance for any slab construction project. - Dimensions: 380mm (L) x 200mm (W) x 230mm (H) - Lightweight: Easy to handle at just 10 kg per unit - Coverage: Requires only 14 blocks per square meter Ideal for efficient, high-quality slab construction.WE OFFER FREE DELIVERY WITHIN NAIROBI

Hollow Pots (380 by 200 by 300)

KSh 115.00

Hollow Pots

Premium hollow pots, engineered for superior strength and durability. Their exceptional quality ensures reliable performance for any slab construction project. - Dimensions: 380mm (L) x 200mm (W) x 300mm (H) - Lightweight: Easy to handle at just 13 kg per unit - Coverage: Requires only 14 blocks per square meter Ideal for efficient, high-quality slab construction.WE OFFER FREE DELIVERY WITHIN NAIROBI

Fundamental Design Principles in EN 1992

Eurocode 2 employs a limit state design philosophy fundamentally different from older permissible stress approaches. Understanding these principles forms the foundation for correctly applying the code.

What is Limit State Design?

Limit state design considers all conditions where a structure ceases to fulfill its intended function. These conditions divide into two categories: ultimate limit states (ULS) and serviceability limit states (SLS).

Ultimate limit states concern structural safety. They include loss of equilibrium, structural failure, and formation of collapse mechanisms. Designs must demonstrate adequate safety margins against these conditions using partial safety factors.

Serviceability limit states address functionality and appearance during normal use. They include excessive deflection, unacceptable crack widths, and vibrations. While not life-threatening, these conditions impair structural performance and user comfort.

This dual approach ensures structures are both safe and functional. It explicitly recognizes that a structure might remain standing but become unusable due to serviceability issues.

Ultimate Limit States (ULS) Explained

ULS design verifies that structural resistance exceeds design loads with appropriate safety margins. The code specifies partial safety factors applied to both loads and material strengths.

For loads, factors account for uncertainty in magnitude and distribution. Dead loads typically use factors around 1.35, while variable loads use 1.5. These values ensure the design considers reasonable worst-case loading scenarios.

For materials, factors account for strength variability and workmanship quality. Concrete uses a factor of 1.5, while reinforcement uses 1.15. These reduce characteristic strengths to design strengths used in calculations.

The verification equation becomes: Design Resistance ≥ Design Effect of Actions

This simple relationship underlies all strength calculations in Eurocode 2. Engineers calculate design effects (moments, shears, axial forces) from factored loads, then ensure provided resistance exceeds these effects.

Serviceability Limit States (SLS) Considerations

SLS checks use unfactored or service loads since they address normal operating conditions. The code specifies limits for deflection, crack width, and stress under service loads.

Deflection limits typically reference span-to-depth ratios or absolute deflection values. For beams and slabs, span/250 often serves as the limit. This ensures floors don’t feel excessively springy or allow damage to finishes and partitions.

Crack width limitations protect reinforcement from corrosion and maintain appearance. Limits vary with exposure conditions, ranging from 0.3mm for aggressive environments to 0.4mm for normal conditions. The code provides formulas calculating expected crack widths based on stress levels, cover thickness, and bar spacing.

Stress limitations prevent excessive creep and ensure concrete remains uncracked under permanent loads. These checks particularly matter for prestressed members where crack control is critical.

What’s the difference between ULS and SLS? ULS concerns structural safety and collapse prevention, using factored loads and reduced material strengths. SLS addresses functionality and appearance under normal service conditions, using unfactored loads and ensuring the structure remains serviceable throughout its design life. Both must be satisfied for compliant design.

Material Properties According to Eurocode 2

Eurocode 2 specifies material properties differently than British Standards. Understanding these specifications ensures correct material selection and verification.

Concrete Strength Classes in Detail

Concrete is designated using a two-number system indicating cylinder and cube strengths. For example, C25/30 means 25 MPa characteristic cylinder strength and 30 MPa characteristic cube strength.

The cylinder strength (first number) represents the design basis. It corresponds to the 5% fractile strength of 150mm diameter, 300mm high cylinders tested at 28 days. This European standard differs from Kenya’s historical use of cube strengths.

Common strength classes in Kenya include:

- C16/20: Mass concrete, blinding

- C25/30: General structural use, ground slabs

- C30/37: Structural frames, elevated slabs

- C35/45: High-rise buildings, heavy loads

- C40/50: Prestressed concrete, special structures

The characteristic compressive strength (fck) forms the basis for design calculations. The design compressive strength (fcd) equals fck divided by the partial safety factor (1.5), giving fcd = 0.67fck for normal design situations.

Elastic modulus values also differ from British Standards. EN 1992 provides the secant modulus (Ecm) which varies with concrete strength. For C30/37 concrete, Ecm equals 33 GPa. This affects deflection calculations and stiffness analysis.

How Do You Determine the Right Concrete Class?

Selection depends on structural requirements, exposure conditions, and durability considerations. For typical residential buildings in Nairobi, C25/30 or C30/37 suffices. High-rise structures exceeding 10 stories generally require C35/45 or stronger.

Exposure conditions influence the choice. Coastal environments with chloride exposure need higher grades for durability. The code links minimum strength classes to exposure classes, ensuring adequate protection against environmental attack.

Reinforcement Specifications

Eurocode 2 recognizes various steel grades designated by yield strength. Common grades include:

- B500A: 500 MPa characteristic yield strength, low ductility

- B500B: 500 MPa characteristic yield strength, medium ductility

- B500C: 500 MPa characteristic yield strength, high ductility

Kenya primarily uses B500B reinforcement, offering good balance between strength and ductility. The “B” indicates ribbed (deformed) bars providing superior bond compared to plain bars.

The design yield strength (fyd) equals the characteristic value divided by 1.15, giving fyd = 435 MPa for B500B steel. This value appears throughout design calculations for flexure, shear, and detailing.

Minimum reinforcement requirements prevent brittle failure. For tension members, the code specifies minimum areas ensuring controlled cracking. For beams, minimum tension reinforcement prevents sudden failure if cracking occurs.

Material Testing Requirements in Kenya

The code requires comprehensive material testing to verify specified properties. Concrete cube tests must achieve at least the characteristic strength, with individual results meeting specified criteria.

Kenya maintains several certified materials testing laboratories accredited by KEBS. These facilities conduct concrete compression tests, reinforcement tensile tests, and other verifications required by the code and NCA regulations.

Testing frequency follows code provisions and project specifications. For concrete, typical requirements include testing every 50m³ or daily, whichever is more frequent. Critical elements may require more intensive testing.

What’s the difference between characteristic and design strength? Characteristic strength represents the 5% fractile value – only 5% of test results fall below this value. Design strength applies partial safety factors to characteristic strength, providing additional safety margins. For example, C30/37 concrete has fck = 30 MPa (characteristic) but fcd = 20 MPa (design) after applying the 1.5 factor.

Design of Reinforced Concrete Elements

EN 1992 provides comprehensive methods for designing various structural elements. Understanding these procedures enables efficient, code-compliant designs.

Beam Design Principles

Beam design addresses flexural capacity, shear resistance, deflection control, and crack width limitation. The process begins with determining design moments and shears from structural analysis.

For flexural design, the code uses stress block parameters defining concrete compression zone behavior. The rectangular stress block simplifies calculations while maintaining accuracy. The compression block depth is limited to prevent over-reinforced sections that fail suddenly without warning.

The design equation relates moment resistance to concrete strength, section dimensions, and reinforcement area. Engineers calculate required steel area, select bars, and verify the section satisfies code requirements.

Minimum and maximum reinforcement limits ensure ductile behavior. Minimum reinforcement prevents brittle failure immediately upon cracking. Maximum limits ensure the neutral axis remains shallow enough for ductile response.

What About Doubly Reinforced Beams?

When moment exceeds the capacity of singly reinforced sections, compression reinforcement becomes necessary. The design procedure accounts for both tension and compression steel contributions.

Compression reinforcement effectiveness depends on whether it yields at ultimate conditions. The code provides criteria determining stress levels in compression bars, affecting their contribution to moment resistance.

Shear Design Methodology

Shear design differs significantly from British Standards. The code uses the variable strut inclination method, allowing engineers to optimize stirrup quantities by adjusting the assumed truss angle.

For members without shear reinforcement, the code provides an empirical formula calculating shear capacity based on concrete strength, section depth, and longitudinal reinforcement ratio. This capacity often suffices for lightly loaded members.

When shear reinforcement is required, the code employs a truss analogy with concrete struts and steel ties. The truss angle (θ) varies between 21.8° and 45°, with shallower angles reducing stirrup requirements but increasing concrete stress.

The design verification checks two conditions: stirrup yielding (ensuring adequate steel) and concrete strut crushing (ensuring concrete can resist compression). Both must be satisfied for a compliant design.

Slab Design Considerations

Slabs represent a significant portion of concrete structures. EN 1992 addresses one-way slabs, two-way slabs, flat slabs, and ribbed slabs.

One-way slabs spanning between beams use simplified bending theory. The code permits using tabular coefficients for moment and shear in continuous slabs, avoiding detailed analysis for standard cases.

Two-way slabs supported on four sides require consideration of moment distribution in both directions. The code provides yield line theory for complex geometries, though finite element analysis is increasingly common for irregular layouts.

Flat slabs without beams need special attention to punching shear around columns. The code specifies detailed checks at multiple critical perimeters, accounting for moment transfer and column geometry. This often governs slab thickness in flat slab systems.

Deflection control frequently governs slab depth selection. The code provides span-to-effective-depth ratios as preliminary sizing guides. For a simply supported slab, the basic ratio is 20, modified for support conditions, concrete strength, and reinforcement percentage.

Column Design Methods

Columns resist axial loads and bending moments, requiring consideration of load eccentricity and slenderness effects. The design process classifies columns as short or slender based on effective length and cross-section dimensions.

Short columns can be designed using interaction diagrams showing the relationship between axial load and moment capacity. These diagrams plot capacity envelopes, with design points falling inside the envelope for safe designs.

Slender columns experience additional moments due to lateral deflection under axial load. The code provides methods calculating these second-order effects, either through rigorous analysis or simplified procedures suitable for regular building frames.

Minimum reinforcement ratios ensure adequate ductility and prevent premature failure. For columns, this typically ranges from 0.15% to 4% of gross concrete area, depending on load levels and detailing philosophy.

Biaxial bending occurs when moments act about both axes simultaneously. The code provides approximate methods checking bi-axial interaction, simplifying what would otherwise require complex three-dimensional analysis.

How do you design columns for earthquake loads? Seismic design requires additional ductility detailing beyond what Eurocode 2 prescribes. While EN 1992 covers basic column design, seismic provisions appear in EN 1998 (Eurocode 8). This includes closer stirrup spacing, confinement requirements, and capacity design principles. For Kenya’s seismic zones, consulting both codes ensures adequate earthquake resistance.

Ready-mix concrete suppliers in Kenyan major cities

Prestressed Concrete Design Under EN 1992

Prestressed concrete represents one of the most efficient structural systems for spanning long distances. EN 1992 provides comprehensive guidance for both pretensioned and post-tensioned members, addressing unique challenges in prestressing design.

The fundamental concept involves applying compressive forces to concrete, counteracting tensile stresses from external loads. This allows concrete to utilize its full compressive strength while minimizing cracking. For Kenya’s infrastructure projects, prestressed concrete offers economical solutions for bridges, parking structures, and long-span buildings.

Pretensioning vs Post-Tensioning: Understanding the Difference

Pretensioning involves stressing high-strength steel tendons before casting concrete. The tendons are anchored to external abutments, stretched to design force, then concrete is cast around them. After the concrete achieves sufficient strength, the tendons are released, transferring prestress force through bond.

This method suits factory production of standardized elements. Many precast manufacturers in Kenya use pretensioning for hollow-core slabs, prestressed beams, and railway sleepers. The controlled factory environment ensures quality and allows efficient mass production.

Post-tensioning applies prestress after concrete hardens. Tendons pass through ducts cast into the concrete. Once concrete reaches design strength, tendons are stressed using hydraulic jacks and anchored at member ends. The ducts may be grouted (bonded) or left ungrouted (unbonded).

Post-tensioning suits cast-in-place construction and irregular geometries. Kenya’s bridge projects increasingly employ this technique, allowing construction of continuous spans without expansion joints. High-rise buildings use post-tensioned flat slabs, reducing structural depth and enabling flexible layouts.

Which method is better for Kenya’s construction? Neither is universally superior. Pretensioning works best for repetitive precast elements where factory production is feasible. Post-tensioning suits unique projects requiring on-site construction. The choice depends on project specifics, contractor capabilities, and economic factors. Both methods have successfully delivered projects across Kenya.

Prestress Loss Calculations: A Critical Component

Prestress force diminishes over time due to various mechanisms. EN 1992 requires calculating these losses to ensure adequate prestress remains throughout the structure’s life.

Immediate losses occur during tensioning and transfer. They include elastic shortening of concrete, friction in ducts (post-tensioning), and anchorage slip. Elastic shortening happens when prestress compresses the concrete, reducing tendon strain. Friction losses occur as tendons curve through ducts, with longer tendons experiencing greater losses.

Time-dependent losses develop gradually from concrete creep, concrete shrinkage, and steel relaxation. Creep causes concrete to deform under sustained prestress, reducing tendon force. Shrinkage as concrete loses moisture creates additional strain reduction. High-strength prestressing steel exhibits relaxation—stress reduction under constant strain.

The code provides detailed formulas for each loss component. Total losses typically range from 20% to 35% of initial prestress, varying with member type, concrete properties, and prestressing method. Accurate loss prediction ensures members retain sufficient prestress for serviceability and ultimate limit states.

Serviceability Checks for Prestressed Members

Prestressed concrete design emphasizes serviceability more than reinforced concrete. The code requires checking stresses, deflections, and crack widths under service loads.

Stress limitations prevent excessive compression causing crushing or excessive tension causing cracking. For fully prestressed members, the code typically limits tensile stress to avoid cracking entirely. For partially prestressed members, controlled cracking is permitted with appropriate crack width checks.

Deflection control ensures members don’t sag excessively. Prestress induces upward camber, potentially causing excessive upward deflection if not properly controlled. The design balances downward dead load deflection with upward prestress camber, achieving acceptable final deflection.

Crack control for partially prestressed members follows similar principles as reinforced concrete but with additional complexity from prestress effects. The code provides formulas considering both prestress and reinforcement contributions to crack width.

Applications in Kenyan Construction

Prestressed concrete has enabled remarkable projects across Kenya. The Standard Gauge Railway bridges extensively use precast prestressed beams. Thika Road superhighway features post-tensioned bridges spanning major intersections. Many modern office buildings in Nairobi employ post-tensioned flat slabs, achieving column-free spaces and reduced structural depth.

The technique offers economic advantages despite higher material costs. Longer spans reduce the number of columns and foundations, often offsetting prestressing expenses. Reduced structural depth lowers overall building height, saving on cladding and services. For high-rise construction, this becomes particularly significant.

Durability and Cover Requirements: Protecting Structures Long-Term

Durability ensures structures maintain performance throughout their design life. EN 1992 addresses durability through appropriate concrete quality, adequate cover, and crack control. These provisions protect reinforcement from corrosion and concrete from deterioration.

Understanding Exposure Classes

The code classifies environmental conditions into exposure classes based on potential deterioration mechanisms. Each class prescribes minimum concrete quality and cover requirements.

XC Classes (Corrosion induced by carbonation):

- XC1: Dry or permanently wet (e.g., building interiors, permanently submerged)

- XC2: Wet, rarely dry (e.g., water tanks, foundations)

- XC3: Moderate humidity (e.g., external concrete sheltered from rain)

- XC4: Cyclic wet and dry (e.g., external concrete exposed to rain)

For most Kenyan buildings, XC3 or XC4 applies depending on rain exposure. Interior elements typically fall under XC1.

XD Classes (Corrosion induced by chlorides):

- XD1: Moderate humidity (e.g., surfaces exposed to airborne chlorides)

- XD2: Wet, rarely dry (e.g., swimming pools, industrial components)

- XD3: Cyclic wet and dry (e.g., bridge decks, coastal structures)

Coastal construction in Mombasa requires XD classification due to chloride-laden sea breezes. Parking garages where de-icing salts might be used also fall under XD classes, though de-icing is rare in Kenya.

XS Classes (Corrosion induced by chlorides from seawater):

- XS1: Exposed to airborne salt but not in direct contact

- XS2: Permanently submerged

- XS3: Tidal, splash and spray zones

Coastal structures like jetties, sea walls, and marine facilities require XS classification. The Mombasa port area presents particularly aggressive exposure requiring careful material selection and detailing.

XF Classes (Freeze-thaw attack): Rarely applicable in Kenya due to tropical climate, except possibly at high elevations experiencing frost.

XA Classes (Chemical attack): Relevant for industrial facilities and structures exposed to aggressive groundwater or soils.

Minimum Cover Specifications by Exposure

Concrete cover provides the physical barrier protecting reinforcement. The code defines cover as the distance from the reinforcement surface (including links) to the nearest concrete surface.

The nominal cover (cnom) equals minimum cover for durability (cmin,dur) plus an allowance for deviation (Δcdev), typically 10mm:

cnom = cmin,dur + Δcdev

Minimum cover for durability increases with exposure severity. For XC3 and concrete class C30/37, cmin,dur = 25mm. For aggressive exposures like XD3 or XS3, minimum covers reach 45-50mm.

The code also requires minimum cover for bond, ensuring adequate load transfer between reinforcement and concrete. For most bars, bond cover equals bar diameter. The final minimum cover is the greater of durability cover and bond cover.

How do you determine the right cover for Kenyan conditions? First, classify the exposure based on environmental conditions. Most building structures use XC3 or XC4. Coastal areas require XD or XS classes. Then, select appropriate concrete class meeting durability requirements—typically C30/37 minimum for XC4. Finally, calculate nominal cover adding the 10mm deviation allowance. For XC4 with C30/37 concrete, nominal cover would be 25mm + 10mm = 35mm for the main reinforcement.

Concrete Quality Requirements

Each exposure class mandates minimum concrete strength and maximum water-cement ratio ensuring adequate density and impermeability. Higher exposure severity requires higher quality concrete.

For XC3/XC4 exposure common in Kenya, minimum concrete class is C25/30 with maximum water-cement ratio of 0.60. More aggressive exposures require C30/37 or higher with reduced water-cement ratios.

The code also specifies minimum cement content ensuring adequate binder for durability. This ranges from 260 kg/m³ for mild exposures to 340 kg/m³ for severe marine exposures.

Kenyan Environmental Considerations

Kenya’s diverse climate creates varied exposure conditions. Nairobi’s moderate highland climate generally presents less aggressive conditions than Mombasa’s humid coastal environment. However, Nairobi’s altitude brings occasional temperature fluctuations requiring attention.

Pollution from traffic and industry in urban areas can accelerate carbonation. Industrial zones may present chemical exposure requiring XA classification. Groundwater conditions vary significantly—some areas have aggressive sulfates requiring sulfate-resistant cement.

Quality control becomes crucial. Using proper concrete mixes, ensuring adequate compaction, and maintaining specified cover during construction determines whether durability provisions work as intended.

Fire Design Requirements (EN 1992-1-2)

Structural fire safety has become increasingly critical as Kenya develops high-rise buildings and complex structures. EN 1992-1-2 provides comprehensive methods ensuring concrete structures maintain load-bearing capacity during fires.

Fire Resistance Periods and Requirements

Fire resistance is measured in standard time periods: R30, R60, R90, R120, R180, R240. The number indicates minutes of fire resistance required. R90 means the structure must support loads for 90 minutes under standard fire exposure.

Kenyan building regulations specify required periods based on building height, occupancy type, and evacuation complexity. Typical requirements include:

- Low-rise residential (up to 4 stories): R60

- Medium-rise commercial (5-15 stories): R90 to R120

- High-rise buildings (over 15 stories): R120 to R180

The National Construction Authority enforces these requirements, ensuring designs demonstrate adequate fire resistance.

The Tabular Method: Simplest Approach

The tabular method provides predetermined dimensions and cover requirements for specified fire resistance periods. This approach requires no calculations, making it most popular for routine building design.

Tables specify minimum member dimensions and axis distance (cover to reinforcement center) for various fire resistance periods. For example, a simply supported beam requiring R90 fire resistance might need minimum width of 200mm and axis distance of 40mm.

The method suits standard structural arrangements with typical loading and support conditions. It assumes standard fire exposure curves and normal weight concrete. Most Kenyan building projects use this approach for its simplicity and conservative results.

Simplified Calculation Methods

For structures not fitting tabular method assumptions, simplified calculations offer more flexibility while avoiding complex thermal analysis. These methods use reduced strength and stiffness values accounting for elevated temperatures.

The 500°C isotherm method considers concrete inside the 500°C isotherm as effective, with full strength. Concrete beyond this temperature is ignored. Charts provide isotherm positions for various exposure durations, allowing engineers to calculate reduced sections resisting fire loads.

The zone method divides members into temperature zones with different strength reductions. This provides more accurate assessment than the isotherm method while remaining relatively simple.

Advanced Calculation Methods

Advanced methods employ sophisticated thermal and structural analysis determining actual temperature distributions and structural response. Finite element programs calculate heat transfer through members, then analyze structural behavior at elevated temperatures.

These methods suit unusual geometries, non-standard loading, or when economy justifies the analysis effort. They require specialist knowledge but can demonstrate adequacy where simpler methods fail or are too conservative.

For most projects in Kenya, the tabular or simplified methods suffice. Advanced methods appear mainly in research or exceptionally complex projects.

Practical Fire Design in Kenya

Fire design integrates with other requirements—adequate cover for durability often exceeds fire requirements. Member sizes dictated by strength or serviceability usually satisfy fire resistance without modification.

However, slender members or lightly loaded elements might require enlargement specifically for fire resistance. Flat slabs sometimes need increased depth or additional reinforcement cover meeting fire requirements.

Precast elements require special attention. Connections and supports must maintain integrity during fires. The code provides guidance ensuring precast systems achieve required fire resistance.

Detailing Requirements: Getting the Details Right

Proper detailing transforms design calculations into buildable, durable structures. EN 1992 prescribes comprehensive detailing rules ensuring reinforcement performs as intended.

Reinforcement Spacing Rules

Minimum spacing ensures concrete can flow around bars during casting, achieving proper compaction. The code requires minimum clear distance between parallel bars equal to the greater of:

- Bar diameter

- Aggregate maximum size plus 5mm

- 20mm

Maximum spacing controls crack widths and distributes reinforcement effectively. For slabs, maximum spacing is typically 3 times the slab depth or 400mm, whichever is less. For beams, spacing varies with crack width requirements.

These rules ensure uniform concrete quality and proper reinforcement distribution. Violating spacing requirements risks inadequate compaction, voids, and reduced structural performance.

Anchorage and Lap Lengths Explained

Reinforcement develops strength through bond with concrete. Adequate length must be embedded for full force transfer. The code specifies basic anchorage length based on bar diameter, concrete strength, and bond conditions.

Good bond conditions exist where bars are cast with adequate concrete below them. Poor bond conditions apply to bars in the upper parts of deep sections where settlement and bleed water reduce bond. Poor conditions require longer anchorage.

The design anchorage length modifies the basic length with factors considering bar stress, confinement from transverse reinforcement, and anchorage type. Standard hooks, bends, or loops at bar ends reduce required length.

Lap splices connect bars by overlapping them a specified distance. The lap length exceeds anchorage length accounting for both bars needing development. Staggering laps prevents weakness planes and improves structural integrity.

Minimum Reinforcement Provisions

Minimum reinforcement prevents brittle failure and controls cracking. Even when calculations suggest no reinforcement is needed, minimums apply.

For tension members, minimum reinforcement equals: As,min = 0.26(fctm/fyk)bt d

Where fctm is mean concrete tensile strength, fyk is reinforcement yield strength, bt is width, and d is effective depth. This ensures reinforcement yields before concrete cracks, providing ductile behavior.

For slabs, minimum reinforcement prevents thermal cracking and distributes loads. Typically 0.13% to 0.26% of section area depending on crack control requirements.

For columns, minimum longitudinal reinforcement (typically 0.10% of section area) ensures adequate compression behavior and provides ductility. Maximum reinforcement (4% of section area) prevents congestion and ensures proper concrete placement.

Crack Control Measures

Cracks in concrete are inevitable but must be controlled. The code limits crack widths based on exposure and appearance requirements. Typical limits range from 0.3mm to 0.4mm for reinforced concrete in building exposure classes.

Crack control achieves through:

- Appropriate reinforcement stress: Lower stresses reduce crack widths

- Bar diameter selection: Many smaller bars control cracks better than few large bars

- Maximum bar spacing: Wider spacing allows wider cracks

- Adequate concrete cover: Protects bars and limits surface crack width

The code provides detailed formulas calculating crack widths considering these factors. For many routine situations, complying with maximum spacing rules ensures acceptable crack widths without explicit calculation.

Why are minimum reinforcement and crack control so important? They ensure structures behave predictably and maintain serviceability. Without minimum reinforcement, sudden brittle failure might occur when concrete cracks. Without crack control, corrosion accelerates, reducing durability. These provisions protect both safety and long-term performance, critical for Kenya’s infrastructure investments.

Differences Between Eurocode 2 and British Standards

Understanding differences between EN 1992 and BS 8110 helps engineers transitioning between standards. While both employ limit state design, significant variations exist.

Design Philosophy Changes

Partial safety factors differ. BS 8110 used γm = 1.5 for concrete and 1.05 for reinforcement at ULS. EN 1992 maintains 1.5 for concrete but uses 1.15 for reinforcement, providing slightly more conservative steel design.

Material characterization changed. BS 8110 used grade (e.g., Grade 30) indicating cube strength. EN 1992 uses strength classes (e.g., C30/37) specifying both cylinder and cube strengths. Cylinder strength forms the design basis, aligning with international practice.

Serviceability approaches differ substantially. BS 8110 emphasized deemed-to-satisfy rules like span-to-depth ratios. EN 1992 focuses more on actual deflection and crack width calculations, though simplified rules exist.

Material Factor Variations

Concrete design strength calculation changed subtly. BS 8110 divided cube strength by 1.5. EN 1992 divides cylinder strength by 1.5, then applies an alpha factor (αcc), typically 0.85, accounting for long-term strength effects. Net effect: fcd = 0.85(fck/1.5) = 0.567fck compared to BS 8110’s 0.67fcu.

Reinforcement design strength increased.

BS 8110’s 1.05 factor gave fyd = fyk/1.05 = 0.95fyk.

EN 1992’s 1.15 factor gives fyd = fyk/1.15 = 0.87fyk. This requires slightly more reinforcement for equivalent capacity.

Bond strength formulas changed, generally giving somewhat different anchorage and lap lengths. The fundamental approach remains similar but specific values differ.

Detailing Requirement Differences

Minimum covers changed. BS 8110 specified nominal covers directly (e.g., 40mm for XC4). EN 1992 requires calculating from durability cover plus deviation allowance, typically giving similar but not identical results.

Reinforcement spacing rules tightened in some aspects. EN 1992’s provisions are more detailed, explicitly addressing aggregate size effects and horizontal versus vertical spacing.

Fire design became more sophisticated. BS 8110 Part 2 provided simpler tables. EN 1992-1-2 offers multiple methods from tabular to advanced analysis, providing greater flexibility.

Practical Implications for Kenyan Engineers

The transition required re-learning familiar procedures. Software tools updated to EN 1992, but engineers must verify outputs rather than blindly trusting results. Understanding both codes helps when reviewing older designs or working on projects started under BS 8110.

Design efficiency changed. Some designs became slightly more conservative, others less so. Overall material quantities remain similar—the codes target equivalent safety levels through different routes.

Training and education investments were necessary. Universities updated curricula. Professional development programs addressed practicing engineers. This knowledge investment positions Kenya’s construction industry for international collaboration.

Software and Tools for EN 1992 Design

Modern structural design relies heavily on computational tools. Numerous software packages support EN 1992 design, from simple calculators to comprehensive analysis programs.

Comprehensive Design Software

The common structural design software are SAP2000 and ETABS from Computers and Structures, Inc. include EN 1992 design modules for frames, shear walls, and slabs. These programs combine structural analysis with automated code checking, generating reinforcement schedules and documentation.

SAFE specializes in slab and foundation design to Eurocodes. It handles flat slabs, post-tensioned slabs, and mat foundations with integrated punching shear and deflection checks.

Tekla Structural Designer provides integrated analysis and design for buildings, with detailed EN 1992 compliance including fire design provisions.

These programs require significant investment but deliver efficiency for complex projects. Most structural consultancies in Nairobi use at least one major analysis package.

Specialized Calculation Tools

Spreadsheet calculators remain popular for element-specific design. Many engineers develop custom Excel tools for routine calculations like beam design, column interaction, or slab thickness determination.

Online calculators provide quick checks and preliminary sizing. Websites offer free EN 1992 calculators for common elements, though these suit preliminary design rather than final documentation.

Mobile apps bring design tools to site, allowing engineers to verify member adequacy or calculate reinforcement on-site. While not replacing rigorous office design, they support informed decision-making during construction.

BIM Integration

Building Information Modeling (BIM) increasingly integrates structural design. Programs like Revit Structure link architectural models with structural analysis, ensuring coordination and reducing errors.

Autodesk Robot Structural Analysis combines with Revit for comprehensive analysis and design. Forces calculated in Robot automatically inform member design, with results linked back to the BIM model.

This integration improves collaboration between architects, structural engineers, and contractors. The NCA encourages BIM adoption for large projects, aligning with international best practices.

What software do most Kenyan engineers use? SAP2000 and ETABS dominate for building design. STAAD.Pro also has significant market share. For bridge design, programs like MIDAS Civil or CSiBridge see regular use. Most firms combine major packages with custom spreadsheets for specific checks. The choice often depends on project type, firm size, and engineer familiarity.

Practical Implementation in Kenya

Applying EN 1992 in Kenya’s context requires understanding local conditions, material availability, and regulatory environment.

Local Material Availability

Concrete constituents are readily available. Several cement manufacturers supply EN 197-1 compliant cement. Quality aggregates exist, though gradation and cleanliness vary by source. Admixtures from major international suppliers are accessible in urban areas.

Ready-mix concrete suppliers in major cities can produce EN 206 compliant concrete for common strength classes. C25/30 and C30/37 are standard. Higher classes like C40/50 require advance ordering and careful quality control.

Reinforcement meeting EN standards is widely available. Local manufacturers produce B500B steel. Imported high-tensile reinforcement for prestressing comes from regional and international sources.

Quality variability remains a challenge. Material testing and quality assurance are essential. Specifying reputable suppliers and enforcing testing protocols ensures design assumptions match reality.

Testing Laboratory Requirements

EN 1992 requires comprehensive material testing. KEBS-accredited laboratories throughout Kenya conduct concrete compression tests, reinforcement tensile tests, and other verifications.

Testing frequency follows code provisions and NCA requirements. Typical protocols include:

- Concrete: One sample per 50m³ or per day

- Reinforcement: One sample per delivery batch or 40 tonnes

- Aggregates: Regular testing for gradation and properties

Calibration and accreditation ensure reliable results. Laboratories must maintain equipment calibration and participate in proficiency testing. The NCA maintains a registry of approved testing facilities.

Engineers must understand test interpretation. Individual results below characteristic values don’t automatically indicate non-compliance—statistical evaluation determines conformity. The code provides specific criteria for assessing test result compliance.

NCA Compliance Requirements

The National Construction Authority enforces building regulations and professional standards. EN 1992 compliance forms part of these requirements.

Design documentation must demonstrate code compliance. This includes design calculations, drawings showing reinforcement details, specifications indicating material requirements, and quality assurance plans.

Professional registration requirements ensure only qualified engineers practice structural design. The NCA maintains registers of structural engineers, requiring academic qualifications, experience, and continuing professional development.

Site supervision by registered professionals ensures designs are properly executed. The NCA requires resident engineers for major projects, verifying construction quality and code compliance.

Cost Implications

Material costs don’t change dramatically with EN 1992. Concrete classes correspond to previous grades, maintaining similar pricing. Reinforcement quantities may vary slightly but overall material budgets remain comparable.

Design time initially increased during the transition as engineers familiarized themselves with new provisions. Experienced practitioners now complete designs as efficiently as under British Standards.

Software investments added costs for firms updating analysis programs. However, improved efficiency often justifies these investments. Some firms using manual calculations under BS 8110 transitioned to software with Eurocodes, gaining overall productivity.

Training costs represented a one-time investment. Universities integrated Eurocodes into curricula. Professional development programs helped practicing engineers. These investments built capacity supporting long-term competitiveness.

Common Challenges and Solutions

Implementing EN 1992 presents several challenges. Understanding these helps engineers navigate the transition successfully.

Understanding National Annexes

National Annexes allow countries to adjust Eurocode provisions for local conditions. They specify values for parameters left open in the main code, like partial safety factors or nominal concrete cover.

Kenya adopted UK National Annexes with minor modifications. Understanding which provisions are nationally determined versus universally fixed requires careful code reading.

Solution: KEBS publishes Kenyan versions incorporating relevant National Annex provisions. Using these versions ensures compliance with locally applicable parameters. When parameters seem unclear, consulting both the main code and National Annex resolves ambiguity.

Material Specification Issues

Specifying materials to EN standards while procuring from suppliers accustomed to British Standards caused initial confusion. Cement types, concrete grades, and reinforcement designations all changed.

Solution: Clear, comprehensive specifications using both EN designations and local terminology bridge the gap. For example, specifying “C30/37 (equivalent to previous Grade 30)” helps suppliers understand requirements. Regular supplier engagement and pre-construction meetings align expectations.

Training Gaps

Many practicing engineers trained under British Standards lacked formal EN 1992 education. Self-study from codes isn’t always sufficient for confident application.

Solution: Professional development through courses, workshops, and mentorship programs addresses knowledge gaps. Engineering consultancies invest in staff training. Universities offer continuing education courses. Professional bodies like the Engineers Board of Kenya facilitate knowledge sharing.

Quality Control Challenges

Ensuring construction matches design intent requires vigilant quality control. Site personnel must understand new detailing requirements and specifications.

Solution: Comprehensive site supervision by engineers familiar with EN 1992 ensures correct implementation. Clear, detailed drawings with notes explaining critical requirements help contractors. Pre-construction training for site supervisors emphasizes new detailing provisions.

What’s the biggest challenge in applying Eurocode 2? Many engineers cite understanding the shift in design philosophy—moving from prescriptive rules to performance-based provisions. EN 1992 offers flexibility but requires deeper understanding of structural behavior. Solving this requires investment in education and building experience through practice. Starting with simpler projects while developing competence helps engineers grow confident with the code.

Case Studies: Eurocode 2 Applications in Kenya

Real projects demonstrate EN 1992’s practical application in Kenya’s construction landscape.

High-Rise Buildings in Nairobi

Britam Tower, Nairobi’s tallest building when completed, employed EN 1992 for its concrete core and columns. The 31-story structure demonstrates code provisions for high-strength concrete, slender columns, and lateral load resistance.

Design challenges included optimizing concrete grades for different heights—using C50/60 at lower levels, stepping down to C40/50 and C35/45 at upper floors. This reduced dead load while maintaining adequate strength. Slenderness effects in tall columns required careful second-order analysis.

The project showcased BIM integration, with Revit models linked to structural analysis. This coordination between architectural and structural designs reduced conflicts and improved construction efficiency.

Bridge Projects

The Nairobi Expressway features numerous bridges designed to EN 1992-2. Post-tensioned continuous spans eliminated joints, improving ride quality and reducing maintenance. Durability design considered Nairobi’s moderate exposure while accommodating heavy traffic loads.

Prestress loss calculations proved critical—long-term deflections needed careful prediction ensuring adequate clearances throughout the design life. The project demonstrated EN 1992’s sophisticated treatment of time-dependent effects.

Industrial Structures

Manufacturing facilities employ EN 1992 for heavy floor slabs and supporting structures. One textile factory in Ruiru designed flat slab floors to accommodate heavy equipment while maintaining flexibility for future reconfiguration.

Punching shear checks around columns governed slab thickness. The code’s detailed punching provisions ensured adequate safety margins. Crack control received special attention given the industrial environment’s potential for corrosion.

Lessons Learned

These projects revealed several insights:

- Early material testing prevents surprises during construction

- Detailed specifications reduce contractor confusion and variation

- Close supervision ensures detailing requirements are met

- Software verification by hand calculations catches occasional errors

- Communication between designers, contractors, and suppliers smooths implementation

The successful projects demonstrate EN 1992’s suitability for Kenya’s diverse construction needs, from residential buildings to major infrastructure.

Order Construction Materials From Us Today

Box Profile (Glossy, Gauge 28)

KSh 650.00

Our Box Profile iron sheets are crafted for superior durability and exceptional weather resistance, making them the ideal choice for long-lasting roofing solutions across Kenya. To make your project even more convenient, we offer free delivery across Kenya when one orders 40 pieces and above. Trust us for reliable products and dependable service for all your building needs.

Box Profile (Glossy)

KSh 470.00

Our Box Profile iron sheets are crafted for superior durability and exceptional weather resistance, making them the ideal choice for long-lasting roofing solutions across Kenya. To make your project even more convenient, we offer free delivery across Kenya when one orders 40 pieces and above. Trust us for reliable products and dependable service for all your building needs.

Box Profile (Matte, Gauge 28)

KSh 680.00

Our Box Profile iron sheets are crafted for superior durability and exceptional weather resistance, making them the ideal choice for long-lasting roofing solutions across Kenya. To make your project even more convenient, we offer free delivery across Kenya when one orders 40 pieces and above. Trust us for reliable products and dependable service for all your building needs.

Box Profile (Matte)

KSh 530.00

Our Box Profile iron sheets are crafted for superior durability and exceptional weather resistance, making them the ideal choice for long-lasting roofing solutions across Kenya. To make your project even more convenient, we offer free delivery across Kenya when one orders 40 pieces and above. Trust us for reliable products and dependable service for all your building needs.

Corrugated Iron Sheet (Gauge 30)

KSh 470.00

Our corrugated iron sheets are crafted for superior durability and exceptional weather resistance, making them the ideal choice for long-lasting roofing solutions across Kenya. To make your project even more convenient, we offer free delivery across Kenya when one orders 40 pieces and above. Each high-quality sheet provides excellent value for money, ensuring your structure is protected for years to come. Trust us for reliable products and dependable service for all your building needs.

Elegantile (Glossy, Gauge 28)

KSh 670.00

Our Elegant Tile profile are crafted for superior durability and exceptional weather resistance, making them the ideal choice for long-lasting roofing solutions across Kenya. To make your project even more convenient, we offer free delivery across Kenya when one orders 40 pieces and above. Trust us for reliable products and dependable service for all your building needs.

Elegantile (Glossy, Gauge 30)

KSh 550.00

Our Elegant Tile profile are crafted for superior durability and exceptional weather resistance, making them the ideal choice for long-lasting roofing solutions across Kenya. To make your project even more convenient, we offer free delivery across Kenya when one orders 40 pieces and above. Trust us for reliable products and dependable service for all your building needs.

Elegantile (Matte, Gauge 28)

KSh 680.00

Our Elegant Tile profile with matte texture are crafted for superior durability and exceptional weather resistance, making them the ideal choice for long-lasting roofing solutions across Kenya. To make your project even more convenient, we offer free delivery across Kenya when one orders 40 pieces and above. Trust us for reliable products and dependable service for all your building needs.

Elegantile (Matte, Gauge 30)

KSh 580.00

Our Elegant Tile profile with matte texture are crafted for superior durability and exceptional weather resistance, making them the ideal choice for long-lasting roofing solutions across Kenya. To make your project even more convenient, we offer free delivery across Kenya when one orders 40 pieces and above. Trust us for reliable products and dependable service for all your building needs.

Versatile (Glossy, Gauge 28)

KSh 670.00

Our versatile iron sheets are crafted for superior durability and exceptional weather resistance, making them the ideal choice for long-lasting roofing solutions across Kenya. To make your project even more convenient, we offer free delivery across Kenya when one orders 40 pieces and above. Trust us for reliable products and dependable service for all your building needs.

Versatile (Glossy, Gauge 30)

KSh 550.00

Our versatile iron sheets are crafted for superior durability and exceptional weather resistance, making them the ideal choice for long-lasting roofing solutions across Kenya. To make your project even more convenient, we offer free delivery across Kenya when one orders 40 pieces and above. Trust us for reliable products and dependable service for all your building needs.

Versatile (Matte, Gauge 28)

KSh 680.00

Our versatile iron sheets are crafted for superior durability and exceptional weather resistance, making them the ideal choice for long-lasting roofing solutions across Kenya. To make your project even more convenient, we offer free delivery across Kenya when one orders 40 pieces and above. Trust us for reliable products and dependable service for all your building needs.

Frequently Asked Questions

What is the main difference between BS 8110 and EN 1992?

EN 1992 uses cylinder strength as the design basis while BS 8110 used cube strength. Partial safety factors differ slightly, with EN 1992 using 1.15 for reinforcement versus BS 8110's 1.05. Serviceability provisions are more detailed in EN 1992, emphasizing calculations over deemed-to-satisfy rules. Overall safety levels remain equivalent, but the path to achieving them varies.

How do I convert between concrete grades and strength classes?

BS 8110 Grade 30 corresponds roughly to C25/30, Grade 35 to C28/35, Grade 40 to C32/40, and Grade 50 to C40/50. The relationship isn't exact because grades specified cube strength while classes specify both cylinder and cube strength. Always verify requirements rather than assuming direct equivalence.

Is EN 1992 mandatory in Kenya?

Yes, the National Construction Authority mandates EN 1992 for all new concrete structure designs since 2021. Projects approved under BS 8110 before the transition could complete under that code, but all new projects require Eurocode compliance.

What concrete class should I use for residential buildings?

C25/30 suffices for most single-family residential construction with typical spans and loads. Multi-story residential buildings typically use C30/37 for structural elements. High-rise residential requires C35/45 or higher depending on loads and member sizes. Always verify through design calculations rather than assuming.

How do I determine fire resistance requirements?

Check local building regulations and NCA requirements based on building height, occupancy type, and evacuation complexity. Typical residential buildings require R60 to R90. Commercial buildings often need R90 to R120. High-rise structures may require R120 to R180. The building approval process clarifies specific requirements for your project.

What is nominal cover and how do I calculate it?

Nominal cover (cnom) equals minimum cover for durability (cmin,dur) plus an allowance for deviation (Δcdev), typically 10mm. Determine exposure class based on environmental conditions, then look up minimum cover requirements in code tables. For example, XC4 with C30/37 requires 25mm minimum, giving 35mm nominal cover.

Can I use British Standard reinforcement with Eurocode 2?

Reinforcement meeting BS 4449 specifications generally satisfies EN 1992 requirements since both standards align closely. Verify the steel grade corresponds to Eurocode designations—B500B is most common in Kenya. Certificates should show compliance with appropriate EN standards.

How do exposure classes work in Kenya's climate?

Most building structures in Kenya fall under XC3 (sheltered external) or XC4 (exposed external). Coastal areas near Mombasa require XD or XS classes due to chloride exposure. Interior elements use XC1. Industrial facilities may need XA classification. Assess each project's specific environmental conditions rather than assuming.

What software is best for Eurocode 2 design?

SAP2000 and ETABS are popular for building frames. SAFE specializes in slabs and foundations. STAAD.Pro has strong market presence. Choice depends on project type, firm size, and engineer experience. Most firms use major analysis software supplemented with spreadsheet calculators for specific checks.