SPECIFIC GRAVITY TEST

SPECIFIC GRAVITY TEST - FUNDAMENTALS AND PROCEDURES

This article explains specific gravity testing fundamentals for construction materials in Kenya. It covers the importance of testing, detailed procedures for coarse and fine aggregates following ASTM standards, equipment requirements, and calculation methods. The guide emphasizes quality control applications and helps construction professionals understand how specific gravity data ensures material quality, proper mix design, and structural integrity in Kenyan construction projects.

Specific gravity test stands as one of the most critical quality control procedures in modern construction. Every building, road, or infrastructure project in Kenya depends on materials that meet exact specifications. Without proper testing, structures risk premature failure, safety hazards, and costly repairs. This test determines whether your construction materials possess the density and strength needed for long-term performance.

The test itself measures how dense a material is compared to water. Think of it as weighing your materials against a universal standard. When engineers in Nairobi specify aggregates for a high-rise or road contractors in Mombasa select materials for highway construction, specific gravity data guides these crucial decisions. The numbers reveal hidden properties that visual inspection cannot detect.

Materials testing laboratories across Kenya perform thousands of specific gravity tests annually. These tests protect investments, ensure structural integrity, and maintain compliance with National Construction Authority regulations. Understanding this fundamental test empowers construction professionals to make informed material selection decisions.

What is Specific Gravity?

Specific gravity represents the ratio of a material’s density to water’s density at a specified temperature. Unlike density measurements that require units, specific gravity is dimensionless. This property helps calculate soil density, void ratio, saturation, and other material characteristics essential for foundation design and structural calculations.

The concept is straightforward. Water serves as the reference point with a specific gravity of 1.0 at 4°C. Materials with specific gravity greater than 1.0 sink in water, while those below 1.0 float. Most construction materials far exceed water’s density. Portland cement typically ranges from 3.10 to 3.16, meaning it’s more than three times denser than water.

This measurement is also known as relative density and quantifies the compactness and strength of materials. The formula remains simple:

Specific Gravity = Density of Material / Density of Water

For practical applications, engineers measure material mass under different moisture conditions. The test accounts for water within pores while excluding surface moisture. This precision matters because aggregate occupies 70-80% of concrete volume. Even small variations in specific gravity affect mix proportions and final strength.

How is Specific Gravity Different from Density?

Density expresses mass per unit volume with specific units (kg/m³ or lb/ft³). Specific gravity compares densities without units. Density changes with temperature and pressure. Specific gravity remains relatively constant since both the material and reference water respond similarly to environmental conditions. Construction professionals prefer specific gravity for consistency across different measurement systems and environmental conditions.

Why Specific Gravity Matters in Construction

Material quality determines project success. Specific gravity serves as a reliable indicator of strength and quality, with higher values generally indicating stronger, less porous materials. This single test reveals multiple material properties simultaneously.

Strength Prediction: Higher specific gravity correlates with higher strength, while low values indicate porous material with reduced strength. Contractors selecting aggregates for structural concrete need materials within specified ranges. Weak aggregates compromise the entire structure.

Mix Design Calculations: Concrete mix design requires precise knowledge of material densities. Engineers calculate the weight of cement, aggregates, and water needed for each cubic meter. Understanding specific gravity helps determine correct material proportions and ensures proper mixing. Incorrect proportions lead to segregation, bleeding, or insufficient strength.

Water Absorption Assessment: The test simultaneously measures water absorption capacity. High-quality aggregates with specific gravity within certain ranges contribute to producing strong and durable concrete. Materials that absorb excessive water steal moisture from cement hydration, weakening the final product.

Quality Control: Tests required for high-rise building construction include specific gravity as a mandatory component. Testing laboratories verify that supplied materials match specifications. Regular testing during construction prevents substandard materials from entering the site.

Cost Optimization: Knowing exact material properties prevents over-ordering or using excessive cement to compensate for weak aggregates. Accurate calculations based on specific gravity data reduce material waste and project costs.

What Happens if Specific Gravity is Not Tested?

Skipping this test invites disaster. Weak aggregates pass undetected until structures fail. Mix designs become guesswork rather than science. Concrete may not achieve specified strength grades. Water absorption problems lead to durability issues. Foundation settlements occur when soil properties are unknown. The small cost of testing pales compared to structural failures or reconstruction expenses.

Construction Materials Requiring Specific Gravity Testing

Specific gravity testing applies to numerous materials including plastics, polymers, rubber, ceramics, and extensively in construction for cement, soils, aggregate, bitumen, and pitch. Each material type requires specific procedures and equipment.

Coarse Aggregates

Coarse aggregates include crushed stone, gravel, and rocks retained on 4.75mm sieves. These materials occupy 70-80% of concrete volume and directly impact properties like strength, durability, and weight. Road construction, concrete structures, and asphalt pavements all depend on quality coarse aggregates. Testing verifies that quarries supply consistent, high-strength materials.

Fine Aggregates

Sand and fine particles passing through 4.75mm sieves constitute fine aggregates. These fill voids between coarse particles and provide workability to concrete mixes. Fine aggregate quality affects surface finish, pumpability, and finishing characteristics. Testing ensures proper gradation and quality for specific applications.

Cement

Portland cement typically has specific gravity around 3.15, while portland-blast-furnace-slag and portland-pozzolan cements may have values near 2.90. The test detects moisture contamination that renders cement useless. Portland cement types available in the Kenyan market must meet strict specific gravity requirements before use.

Soil

Specific gravity is a key parameter in soil mechanics, aiding in classification and assessment of different soil types including sands, silts, and clays. Foundation design requires accurate soil data. Geotechnical surveys rely on specific gravity to predict settlement and bearing capacity. Different soil types exhibit distinct specific gravity values that inform engineering decisions.

Bitumen and Asphalt

Road construction materials require specific gravity testing to ensure proper mix design. Asphalt binder content calculations depend on accurate density measurements. Testing helps achieve optimal performance and durability in pavement construction.

Which Materials Require Specific Gravity Testing in Kenya?

Kenyan regulations mandate testing for all aggregates used in structural concrete and road construction. Cement testing is required for quality assurance. Soil investigations for foundations must include specific gravity determinations. Any material affecting structural integrity needs testing at certified materials testing laboratories.

Specific Gravity Test for Coarse Aggregates

ASTM C127 specifies the standard for specific gravity and absorption of coarse concrete, providing definite measurement procedures that ensure consistency. This globally recognized standard guides laboratory testing across Kenya’s construction industry.

Understanding ASTM C127 Standard

The standard covers particles retained on 4.75mm sieves. It determines relative density expressed as oven-dry (OD), saturated-surface-dry (SSD), or apparent relative density. Each condition reveals different material characteristics:

- Oven-Dry (OD): Material dried at 110°C until constant mass

- Saturated-Surface-Dry (SSD): Pores filled with water but surface dry

- Apparent: Excludes permeable pores

Equipment Required

Professional testing demands specific apparatus:

- Precision balance capable of weighing to 0.5g accuracy

- Wire basket with maximum 6.3mm mesh openings

- Water tank large enough for basket immersion

- Thermostatically controlled oven maintaining 100-110°C

- Absorbent cloths for surface drying

- Sample containers with airtight seals

Unit weight of materials in construction calculations depend on properly calibrated equipment. Testing laboratories invest significantly in maintaining equipment accuracy.

Testing Procedure Step-by-Step

Step 1: Sample Preparation Wash approximately 2kg of aggregate thoroughly to remove dust and fines. This cleaning step prevents contamination that skews results. Dry the sample in the oven at 110°C for 24 hours until achieving constant mass.

Step 2: Saturation Immerse the oven-dried sample in water at room temperature for 24±4 hours. This soaking period ensures water completely penetrates accessible pores. The duration matters because insufficient soaking produces inaccurate absorption values.

Step 3: Surface Drying Remove the sample from water and drain. Spread material on absorbent cloths. Roll particles gently until surface water disappears but aggregate still appears moist. Achieving the saturated-surface-dry condition requires careful attention to avoid over-drying or leaving surface moisture.

Step 4: SSD Mass Determination Weigh the saturated-surface-dry aggregate immediately. Record this weight as “B” in calculation formulas. Speed matters here because surface moisture evaporates quickly, changing the measurement.

Step 5: Immersed Weight Place the SSD aggregate in the wire basket. Immerse the basket completely in water at 23±2°C. Remove air bubbles by gentle agitation. Weigh the suspended basket and aggregate. Record this immersed weight as “C”.

Step 6: Oven-Dry Mass Return the sample to the oven. Dry at 110°C for 24 hours until reaching constant mass. Cool in airtight containers to prevent moisture absorption. Weigh and record as “A”.

Calculations and Formulas

Standard formulas calculate different specific gravity values:

Specific Gravity (OD) = A / (B – C)

Specific Gravity (SSD) = B / (B – C)

Apparent Specific Gravity = A / (A – C)

Water Absorption (%) = [(B – A) / A] × 100

Where:

- A = Oven-dry mass in air

- B = Saturated-surface-dry mass in air

- C = Mass of saturated sample in water

Most specifications reference SSD specific gravity for mix design purposes. The absorption percentage indicates material porosity and durability characteristics.

What is the Acceptable Range for Coarse Aggregate Specific Gravity?

Quality coarse aggregates typically range from 2.4 to 2.9. Normal weight concrete aggregates average around 2.6 to 2.7. Values below 2.4 suggest porous, weak material. Lightweight aggregates intentionally exhibit lower values. Heavy aggregates used for radiation shielding exceed 3.0. Local geology determines typical ranges. Kenyan quarries produce aggregates generally falling within standard ranges, though testing confirms each source meets project requirements.

Specific Gravity Test for Fine Aggregates

ASTM C128 and AASHTO T84 tests determine specific gravity and absorption values for mineral aggregates passing 4.75mm sieves. Fine aggregate testing differs significantly from coarse aggregate procedures due to particle size.

ASTM C128 Standard Overview

The standard addresses sand and fine particles that behave differently than larger stones. Surface moisture on fine particles creates greater measurement challenges. Small particle size increases surface area relative to volume, making surface drying more critical.

The Pycnometer Method

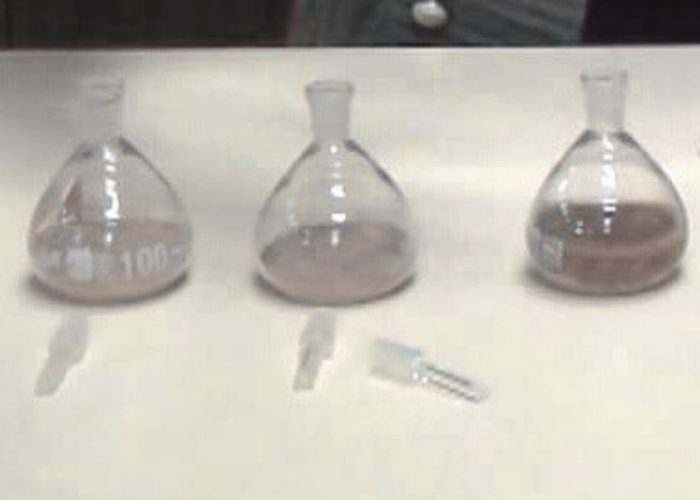

The gravimetric test procedure uses a Volumetric Flask or Jar Pycnometer for weighing the immersed sample. This specialized flask allows accurate volume measurements essential for fine materials. Alternative methods use Le Chatelier flasks with smaller specimens.

Equipment and Materials Needed

- Pycnometer or volumetric flask (500ml capacity)

- Analytical balance reading to 0.1g

- Conical mold and tamper for SSD condition determination

- Thermometer accurate to 0.5°C

- Oven maintaining 110±5°C

- Hot plate or stove for removing air bubbles

- Clean water at calibrated temperature

Testing Procedure Explained

Sample Selection: Take approximately 1kg of fine aggregate passing the 4.75mm sieve. Thoroughly mix and reduce by quartering to obtain 500g representative sample.

Moisture Conditioning: Dry the sample to constant mass at 110°C. Cool in airtight containers. Add measured water and mix thoroughly. Leave overnight to achieve uniform moisture distribution.

SSD Determination: Fill the conical mold with damp sand using 25 tamping strokes. Remove the mold vertically. Sand should slump slightly but maintain cone shape. This indicates saturated-surface-dry condition. If it flows or collapses, dry more and repeat. If it maintains shape completely, add more moisture.

Pycnometer Filling: Weigh the pycnometer empty (W₁). Add approximately 500g of SSD sand (W₂). Add water to about 90% capacity. Roll the pycnometer to eliminate air bubbles. Place on hot plate briefly if needed to release trapped air. Cool to calibration temperature. Fill to graduation mark. Weigh (W₃).

Water Calibration: Empty, clean, and dry the pycnometer. Fill with water only to the calibration mark at test temperature. Weigh (W₄).

Final Drying: Transfer sand from pycnometer to container. Dry at 110°C for 24 hours. Cool and weigh to determine oven-dry mass.

Calculation Formulas

Specific Gravity (SSD) = W₂ / (W₄ – W₃ + W₂)

Where:

- W₁ = Mass of empty pycnometer

- W₂ = Mass of SSD sand

- W₃ = Mass of pycnometer + sand + water

- W₄ = Mass of pycnometer filled with water only

The calculation accounts for the volume of water displaced by sand particles.

How Does Fine Aggregate Testing Differ from Coarse Aggregate?

Fine aggregates require pycnometer methods due to particle size. Surface area per unit weight is much higher, making surface moisture control critical. The conical mold test determines SSD condition instead of visual inspection and cloth drying used for coarse aggregates. Air removal becomes more challenging with fine materials. Temperature control matters more because fine aggregate testing uses smaller water volumes where temperature affects results significantly.

Order Construction Materials From Us Today

Box Profile (Glossy, Gauge 28)

KSh 650.00

Our Box Profile iron sheets are crafted for superior durability and exceptional weather resistance, making them the ideal choice for long-lasting roofing solutions across Kenya. To make your project even more convenient, we offer free delivery across Kenya when one orders 40 pieces and above. Trust us for reliable products and dependable service for all your building needs.

Box Profile (Glossy)

KSh 470.00

Our Box Profile iron sheets are crafted for superior durability and exceptional weather resistance, making them the ideal choice for long-lasting roofing solutions across Kenya. To make your project even more convenient, we offer free delivery across Kenya when one orders 40 pieces and above. Trust us for reliable products and dependable service for all your building needs.

Box Profile (Matte, Gauge 28)

KSh 680.00

Our Box Profile iron sheets are crafted for superior durability and exceptional weather resistance, making them the ideal choice for long-lasting roofing solutions across Kenya. To make your project even more convenient, we offer free delivery across Kenya when one orders 40 pieces and above. Trust us for reliable products and dependable service for all your building needs.

Box Profile (Matte)

KSh 530.00

Our Box Profile iron sheets are crafted for superior durability and exceptional weather resistance, making them the ideal choice for long-lasting roofing solutions across Kenya. To make your project even more convenient, we offer free delivery across Kenya when one orders 40 pieces and above. Trust us for reliable products and dependable service for all your building needs.

Corrugated Iron Sheet (Gauge 30)

KSh 470.00

Our corrugated iron sheets are crafted for superior durability and exceptional weather resistance, making them the ideal choice for long-lasting roofing solutions across Kenya. To make your project even more convenient, we offer free delivery across Kenya when one orders 40 pieces and above. Each high-quality sheet provides excellent value for money, ensuring your structure is protected for years to come. Trust us for reliable products and dependable service for all your building needs.

Elegantile (Glossy, Gauge 28)

KSh 670.00

Our Elegant Tile profile are crafted for superior durability and exceptional weather resistance, making them the ideal choice for long-lasting roofing solutions across Kenya. To make your project even more convenient, we offer free delivery across Kenya when one orders 40 pieces and above. Trust us for reliable products and dependable service for all your building needs.

Elegantile (Glossy, Gauge 30)

KSh 550.00

Our Elegant Tile profile are crafted for superior durability and exceptional weather resistance, making them the ideal choice for long-lasting roofing solutions across Kenya. To make your project even more convenient, we offer free delivery across Kenya when one orders 40 pieces and above. Trust us for reliable products and dependable service for all your building needs.

Elegantile (Matte, Gauge 28)

KSh 680.00

Our Elegant Tile profile with matte texture are crafted for superior durability and exceptional weather resistance, making them the ideal choice for long-lasting roofing solutions across Kenya. To make your project even more convenient, we offer free delivery across Kenya when one orders 40 pieces and above. Trust us for reliable products and dependable service for all your building needs.

Elegantile (Matte, Gauge 30)

KSh 580.00

Our Elegant Tile profile with matte texture are crafted for superior durability and exceptional weather resistance, making them the ideal choice for long-lasting roofing solutions across Kenya. To make your project even more convenient, we offer free delivery across Kenya when one orders 40 pieces and above. Trust us for reliable products and dependable service for all your building needs.

Versatile (Glossy, Gauge 28)

KSh 670.00

Our versatile iron sheets are crafted for superior durability and exceptional weather resistance, making them the ideal choice for long-lasting roofing solutions across Kenya. To make your project even more convenient, we offer free delivery across Kenya when one orders 40 pieces and above. Trust us for reliable products and dependable service for all your building needs.

Versatile (Glossy, Gauge 30)

KSh 550.00

Our versatile iron sheets are crafted for superior durability and exceptional weather resistance, making them the ideal choice for long-lasting roofing solutions across Kenya. To make your project even more convenient, we offer free delivery across Kenya when one orders 40 pieces and above. Trust us for reliable products and dependable service for all your building needs.

Versatile (Matte, Gauge 28)

KSh 680.00

Our versatile iron sheets are crafted for superior durability and exceptional weather resistance, making them the ideal choice for long-lasting roofing solutions across Kenya. To make your project even more convenient, we offer free delivery across Kenya when one orders 40 pieces and above. Trust us for reliable products and dependable service for all your building needs.

Specific Gravity Test for Cement

Cement specific gravity is determined by the Le-Chatelier’s Flask Method, with Ordinary Portland Cement typically having a value around 3.15, while Portland Pozzolana cement is around 2.90. This test verifies cement quality before construction begins and detects moisture contamination that renders cement worthless.

Understanding the Le Chatelier Flask Method

The Le-Chatelier’s flask consists of thin glass with a bulb at the bottom having a mean diameter of 7.8cm and capacity of 250ml, with graduated stem markings in millimeters. The design allows precise volume displacement measurements essential for determining cement density.

We use kerosene instead of water as the reference substance because cement reacts with water to form calcium oxide through hydration, while kerosene causes no reaction. This critical difference ensures accurate measurements without chemical interference.

Equipment Requirements

Professional cement testing demands specialized apparatus:

- Le Chatelier flask with precise graduations

- Analytical balance reading to 0.1g accuracy

- Kerosene (specific gravity 0.79, water-free)

- Constant temperature water bath maintaining uniform conditions

- Glass stirring rod for air bubble removal

- Funnel with non-corrosive smooth surface

- Thermometer accurate to 0.5°C

The flask holds approximately 250ml, with an oval bulb in the neck holding 17ml, graduated from 0 to 1.0ml in 0.1ml subdivisions below the bulb, and 18 to 24ml above the bulb.

Procedure Steps Explained

Step 1: Flask Preparation The flask should be completely free from liquid and fully dry before starting, then weigh the empty flask and record as W1. Any moisture affects results because cement immediately begins hydrating when exposed to water.

Step 2: Adding Cement Fill cement into the bottle up to half the flask, approximately 50gm, and weigh it with its stopper, recording as W2. Use fresh cement from sealed containers. Lumpy or hardened cement indicates moisture contamination and should be rejected.

Step 3: Kerosene Addition Add kerosene to the cement up to the top of the bottle and mix well to remove air bubbles. Insert the glass nipple and gently tilt the flask to release trapped air bubbles until no further bubbles rise to the liquid surface. Complete air removal is crucial for accuracy.

Step 4: Weighing with Kerosene Weigh the flask with cement and kerosene, recording it as W3. Handle the flask carefully by the rim only to avoid temperature changes from hand contact.

Step 5: Reference Measurement Empty the flask, fill the bottle with kerosene up to the top, and weigh the flask to count W4. This establishes the kerosene baseline for calculations.

Calculation Formula

Specific Gravity of Cement = (W2 – W1) / [(W4 – W1) – (W3 – W2)]

Where:

- W1 = Mass of empty flask

- W2 = Mass of flask + cement

- W3 = Mass of flask + cement + kerosene

- W4 = Mass of flask + kerosene only

The formula calculates the volume of kerosene displaced by cement particles, revealing true cement density.

Interpretation of Results

Good cement should have specific gravity of 3.1-3.6 g/cc, with ordinary Portland cement at 3.15 g/cc as the standard for nominal mix design. If specific gravity reaches 3.19, it indicates cement pores are filled with moisture content, and cement exposed to extreme moisture may show this elevated reading.

Excessive moisture content affects workability and strength of cement, and cement becomes useless once hydrated with water. Old cement bags showing lumps indicate moisture contamination and should be tested before use.

What is the Standard Specific Gravity of Portland Cement?

According to the Portland Cement Association Design and Control of Concrete Mixtures from 1988, Ordinary Portland Cement has specific gravity approximately 3.15, while Portland-Blast-Furnace-Slag and Portland-Pozzolan cements have values near 2.90. Different cement types naturally exhibit varying specific gravity values based on their mineral composition and manufacturing process. Portland cement types available in the Kenyan market must be tested to verify they meet standard specifications.

Specific Gravity Test for Soil

ASTM D854 and AASHTO T100 test methods cover determination of specific gravity for soil solids passing the 4.75mm sieve by means of water pycnometer. Geotechnical engineering relies heavily on accurate soil specific gravity data for foundation design and earthwork calculations.

Importance in Foundation Design

Specific gravity of soil solids is used in calculating phase relationships such as void ratio and degree of saturation, and to calculate soil solids density by multiplying specific gravity by water density at proper temperature. These calculations determine bearing capacity, settlement potential, and compaction requirements.

Foundation failures often trace back to inadequate soil investigation. Specific gravity is a key parameter in soil mechanics, aiding in classification and assessment of different soil types including sands, silts, and clays. Each soil type exhibits characteristic specific gravity ranges that identify material composition and engineering properties.

Testing Methodology Overview

Two methods are provided – Method A for moist specimens is preferred and mandatory for organic soils, highly plastic fine-grained soils, tropical soils, and soils containing halloysite; Method B covers oven-dry specimens. Kenya’s diverse soil conditions often require Method A due to tropical climate effects and high clay content in many regions.

Equipment Required:

- Water pycnometer (stoppered flask or volumetric flask)

- Precision balance with 0.01g readability

- Drying oven at 110±5°C

- Thermometer measuring to 0.5°C accuracy

- Vacuum pump or hot plate for air removal

- Insulated container for thermal equilibrium

- Desiccator for cooling specimens

- No. 4 sieve (4.75mm opening)

Simplified Procedure

The test specimen size is not predetermined but determined by a table in the test method based on soil classification from ASTM D2487, with recommended mass ranges for different soil types. Proper sample size ensures representative testing and accurate results.

Calibration of pycnometers is the first phase, which is time-consuming but can be performed for up to six pycnometers simultaneously, and only needs performing once unless pycnometer mass deviates from calibrated value by 0.06g or more. Well-calibrated equipment is essential for reliable data.

The testing process involves saturating soil particles, removing air bubbles, and measuring displaced water volume. Temperature control throughout testing ensures consistency. Multiple readings verify accuracy, with duplicate results agreeing within specified tolerances.

Applications in Geotechnical Engineering

Soil specific gravity data calculates crucial engineering parameters:

Void Ratio: Determines pore space available for water or air Porosity: Indicates drainage and permeability characteristics Degree of Saturation: Reveals moisture content relative to void space Unit Weight: Essential for earth pressure and stability calculations

Foundation types suitable for different Kenyan soils depend heavily on these calculated parameters. Black cotton soils around Nairobi require special attention due to high clay content and swelling properties. Why geotechnical survey is important in any construction project becomes clear when considering how soil properties affect structural stability.

How Does Soil Specific Gravity Affect Foundation Design?

Soil specific gravity reveals mineral composition and density. Higher values indicate dense, stable soils suitable for shallow foundations. Lower values suggest porous or organic soils requiring deep foundations or ground improvement. The data helps engineers select appropriate foundation types, calculate bearing capacity, and predict settlement behavior. Combined with other tests like the Standard Penetration Test and California Bearing Ratio test, specific gravity provides comprehensive soil characterization.

Materials Testing Laboratories in Kenya

Kenya’s construction industry depends on certified materials testing laboratories that maintain international standards and provide reliable data. These facilities ensure construction materials meet specifications before incorporation into projects.

SGS Kenya Limited

SGS is a leading provider of laboratory testing services with a global network of ISO/IEC 17025 accredited laboratories, offering comprehensive testing for metals, polymers, industrial lubricants, and broad ranges of mechanical, physical, chemical and non-destructive testing methods. Their Mombasa facility maintains multiple accreditation scopes.

SGS Kenya is accredited by SANAS (South Africa National Accreditation System) under Facility Number T0151 for petroleum, food and agricultural products, potable water, waste water, agricultural and environmental soils, and fats and oils testing. This accreditation guarantees results meet international standards and are recognized globally.

The laboratory performs specific gravity testing for various construction materials using ASTM and ISO methodologies. Their experienced staff understands both international requirements and local construction practices. Projects requiring quality certification benefit from SGS’s global recognition and technical expertise.

GeoIssa Geotechnical Services

This specialized firm focuses on geotechnical investigations and soil testing throughout Kenya. They provide comprehensive soil analysis including specific gravity determinations for foundation design projects. Their mobile laboratories reach remote construction sites, delivering rapid turnaround times for critical path projects.

GeoIssa maintains modern equipment calibrated to international standards. Their engineers interpret test results within the context of local geology and construction practices. Many major infrastructure projects in Nairobi, Mombasa, and Kisumu rely on their testing services.

Norken International Limited

Norken operates testing laboratories offering materials verification for construction projects. They test aggregates, cement, concrete, and soil samples following ASTM and British Standards procedures. Their quality control services help contractors maintain specification compliance throughout project execution.

The facility provides both routine testing for ongoing projects and specialized investigations for forensic analysis. Their reports meet National Construction Authority regulations requirements, facilitating smooth project approvals and certifications.

Equipment Availability and Standards Compliance

Modern testing laboratories in Kenya invest significantly in equipment and training. Facilities maintain:

- Calibrated pycnometers for various material types

- Precision analytical balances with environmental controls

- Temperature-controlled ovens for specimen preparation

- Constant temperature water baths ensuring accuracy

- Vacuum equipment for air removal

- Data management systems for quality assurance

Regular equipment calibration follows manufacturer specifications and international standards. Most facilities participate in proficiency testing programs that verify accuracy against other laboratories worldwide. This quality assurance process builds confidence in reported results.

Applications of Specific Gravity Data

Construction professionals apply specific gravity data throughout project lifecycles. Understanding material properties enables informed decision-making and quality control.

Concrete Mix Design

Proportioning Calculations: Engineers calculate exact quantities of cement, aggregates, and water needed for each cubic meter of concrete. Specific gravity plays a significant role in concrete mix design by determining correct proportions of cement, water, and aggregates to achieve desired strength and durability.

Volume to Weight Conversions: Mix designs specify volumes, but materials are batched by weight. Specific gravity converts between these units accurately. On-site concrete mixing best practices require precise measurements for consistent quality.

Yield Calculations: Specific gravity data predicts actual concrete volume produced from given material quantities. This prevents shortages or excess during placing operations.

Quality Control in Construction

Material Verification: Every aggregate source requires testing before approval. Specific gravity confirms materials match specifications. Quarries supplying substandard aggregates are identified and rejected.

Batch-to-Batch Consistency: Regular testing during construction verifies material consistency. Significant variations trigger investigations and corrective actions. Ready mix concrete suppliers in Kenyan major cities maintain strict quality control using specific gravity data.

Strength Prediction: Specific gravity correlates with aggregate strength and concrete performance. Testing programs include specific gravity alongside other quality indicators for comprehensive material assessment.

Material Selection

Performance Requirements: Different applications need specific material properties. High-strength concrete requires dense aggregates with appropriate specific gravity. Lightweight concrete uses materials with lower values.

Cost Optimization: Testing prevents purchasing expensive cement to compensate for weak aggregates. Selecting materials with correct specific gravity ensures efficient mix designs using minimum cement content while achieving required strength.

Durability Considerations: Materials with proper specific gravity ranges exhibit better resistance to weathering, freeze-thaw cycles, and chemical attack. Long-term performance depends on selecting quality materials verified through testing.

Compliance Verification

Tests required for high-rise building construction in Kenya include mandatory specific gravity testing. Regulatory authorities require documented proof that materials meet specifications. Laboratory reports become part of permanent project records used during inspections and certifications.

How is Specific Gravity Used in Concrete Proportioning?

Specific gravity converts aggregate volumes to weights for accurate batching. It calculates water absorption to adjust mix water quantities. The absolute volume method of mix design relies entirely on specific gravity values to determine material proportions that completely fill the concrete volume without voids or excess paste. Without accurate specific gravity data, concrete mixes become trial-and-error experiments rather than scientific calculations.

Common Mistakes and How to Avoid Them

Testing accuracy depends on proper technique and attention to detail. Understanding common errors prevents unreliable results that compromise construction quality.

Sample Preparation Errors

Insufficient Washing: Dust and fines coating aggregates alter measurements. Thoroughly wash all samples until rinse water runs clear. Organic matter and clay particles particularly affect results when not removed completely.

Incomplete Drying: Residual moisture in oven-dried samples causes low specific gravity readings. Dry samples to constant mass, defined as less than 0.1% weight change between successive measurements. Cool specimens in airtight containers preventing moisture absorption during cooling.

Contamination: Use clean equipment for each material type. Cement residue in aggregate testing equipment produces false readings. Store materials in sealed containers preventing foreign matter introduction.

Moisture Content Issues

Over-Drying Fine Aggregates: Excessive drying makes achieving SSD condition difficult. Fine materials require careful moisture conditioning. The conical mold test determines proper SSD state objectively.

Under-Saturating Coarse Aggregates: Insufficient soaking time leaves pore centers dry while surfaces appear saturated. Always soak coarse aggregates for the full 24±4 hour period specified in standards.

Surface Water Neglect: Surface moisture on SSD specimens adds weight without displacing water during immersed weighing. Master the surface drying technique using absorbent cloths for coarse aggregates and conical mold testing for fine materials.

Equipment Calibration Problems

Balance Accuracy: Precision balances drift over time. Regular calibration using certified weights maintains accuracy. Record calibration dates and results for quality assurance documentation.

Temperature Variations: Water density changes with temperature, affecting specific gravity calculations. Maintain constant temperature during testing or apply temperature correction factors from standard tables.

Pycnometer Volume: Flask volumes change slightly with repeated use and cleaning. Recalibrate pycnometers periodically following standard procedures. Small volume errors accumulate into significant specific gravity deviations.

Calculation Mistakes

Formula Misapplication: Different specific gravity types use different formulas. Clearly identify whether results report OD, SSD, or apparent specific gravity. Mix design typically requires SSD values.

Rounding Errors: Premature rounding during calculations compounds errors. Maintain four significant digits throughout calculations, rounding only final results to appropriate precision.

Unit Confusion: Ensure consistent units throughout calculations. Mixing grams with kilograms or milliliters with liters produces nonsensical results. Double-check all measurements before calculating.

Cost Implications in Kenya

Understanding testing costs helps budget construction projects realistically. Quality testing represents a small investment preventing expensive failures.

Testing Fees at Certified Laboratories

Aggregate Specific Gravity: KES 3,000 – 5,000 per sample depending on laboratory and turnaround time. Rush testing costs more but provides results within 24-48 hours for urgent projects.

Cement Testing: KES 2,500 – 4,000 per sample including specific gravity and other standard tests. Comprehensive cement analysis packages offer better value when multiple parameters need verification.

Soil Testing: KES 4,000 – 7,000 per specific gravity test depending on sample complexity and soil type. Geotechnical investigation packages combining multiple tests reduce per-test costs significantly.

Mobile Laboratory Services: On-site testing costs more due to equipment transport and setup. Expect premiums of 30-50% over laboratory testing for the convenience of site access and rapid results.

Equipment Costs

Basic Laboratory Setup: Establishing a site laboratory for routine testing requires initial investment of KES 500,000 – 1,000,000. This includes pycnometers, balances, ovens, and basic equipment.

Precision Equipment: High-accuracy balances and calibrated glassware represent significant costs. Budget KES 150,000 – 300,000 for reliable analytical balances alone. Quality equipment pays for itself through accurate results and reduced recalibration requirements.

Consumables and Maintenance: Regular expenses include calibration weights, replacement glassware, oven maintenance, and balance servicing. Budget KES 50,000 – 100,000 annually for well-used laboratory facilities.

Impact on Project Budgets

Testing Allocation: Reserve 0.5-1.0% of material costs for quality testing. This modest investment protects the remaining 99% of expenditures from material deficiencies.

Failure Cost Avoidance: Demolishing and replacing structures built with substandard materials costs 10-20 times more than comprehensive testing programs. One prevented failure justifies years of testing expenses.

Insurance and Liability: Documented testing reduces insurance premiums and limits liability exposure. Quality assurance records demonstrate due diligence protecting contractors and owners from claims.

Regulatory Framework in Kenya

Construction quality depends on regulatory oversight ensuring materials meet minimum standards. Kenya’s framework balances safety requirements with practical implementation.

NCA Requirements

The National Construction Authority mandates materials testing for registered projects. Contractors must submit laboratory reports documenting aggregate, cement, and soil properties before construction proceeds beyond foundation level.

Registration Conditions: NCA-registered contractors commit to using approved materials tested at certified laboratories. Registration categories determine project values contractors can undertake, with higher categories requiring more comprehensive quality control programs.

Inspection Protocols: NCA inspectors verify testing frequency matches project requirements. Major structural elements need documented materials approval before casting. Non-compliance triggers stop-work orders and potential registration suspension.

British Standards Compliance

Kenya predominantly follows British Standards (BS) and Eurocodes for construction specifications. Material testing procedures reference BS and ASTM standards interchangeably, with specific project specifications defining applicable standards.

BS 882 for Aggregates: Specifies aggregate properties including specific gravity requirements. Projects designed to British Standards must verify aggregates meet BS 882 specifications through testing.

BS 12 for Portland Cement: Defines cement properties and testing methods. Cement supplied to Kenyan construction sites should demonstrate BS 12 compliance through manufacturer testing and independent verification.

Integration with Local Practices: While international standards guide testing, laboratories adapt procedures to local materials and conditions. Red volcanic soils around Nairobi require specialized testing approaches not explicitly covered in standard procedures.

Quality Assurance Protocols

Three-Level Testing: Manufacturer certification, contractor verification, and independent third-party testing provide multiple checks ensuring material quality. Each level serves distinct purposes in comprehensive quality assurance.

Documentation Requirements: Maintain complete records including sample identification, testing dates, laboratory certificates, and technician signatures. These documents support project handover and future maintenance or modifications.

Audit Trails: Quality management systems track materials from source through testing to incorporation in permanent works. Digital systems increasingly replace paper records, improving traceability and access.

Frequently Asked Questions

What is the Difference Between Specific Gravity and Bulk Density?

Specific gravity compares material density to water without units. Bulk density expresses mass per volume including air voids between particles, typically in kg/m³. Aggregate bulk density includes particle density plus voids between particles. Specific gravity measures only particle density excluding voids. Both properties matter for concrete mix design but serve different purposes.

How Long Does a Specific Gravity Test Take?

Coarse aggregate testing requires 48-72 hours including 24-hour saturation, testing procedures, and oven drying verification. Fine aggregate testing takes 36-48 hours with overnight moisture conditioning. Cement testing completes in 2-3 hours using Le Chatelier flask method. Soil testing requires 24-36 hours depending on method and sample preparation. Rush services offer accelerated timelines at premium costs but may compromise accuracy.

Can Specific Gravity Testing Be Done On-Site?

Yes, with proper equipment and trained personnel. Site laboratories conduct routine testing for large projects where immediate results justify equipment investment. Portable balances, field ovens, and pycnometers enable on-site testing. However, environmental conditions affect accuracy. Temperature fluctuations, dust, and vibration challenge precision measurements. Critical structural applications should verify site results with certified laboratory testing.

What Equipment is Needed for Specific Gravity Testing?

Essential equipment includes precision balances (0.1g for cement and soil, 0.5g for aggregates), pycnometers or volumetric flasks, temperature-controlled ovens maintaining 110±5°C, water baths for constant temperature, thermometers accurate to 0.5°C, and sample containers. Supporting equipment includes sieves for particle separation, vacuum pumps or hot plates for air removal, desiccators for specimen cooling, and absorbent cloths for surface drying. Total investment ranges from KES 200,000 for basic setups to over KES 1,000,000 for comprehensive laboratories.

How Often Should Aggregates Be Tested?

Testing frequency depends on project size and quality control requirements. General guidelines recommend testing each new aggregate source before approval, retesting when sources change locations or characteristics visibly differ, and periodic verification testing every 500-1000 cubic meters of concrete produced. Large projects establish statistical quality control programs with planned testing frequencies. Small projects may test once if aggregate source remains constant. Always retest if material quality appears questionable regardless of schedule.

What Are the Consequences of Using Materials with Incorrect Specific Gravity?

Weak aggregates with low specific gravity produce concrete below design strength, risking structural failures. Materials exceeding specified ranges may cause workability problems and finishing difficulties. Incorrect specific gravity values used in mix design calculations produce wrong material proportions, leading to excess cement waste or insufficient strength. Moisture-contaminated cement with elevated specific gravity performs poorly, potentially failing to achieve adequate strength. Foundation designs based on inaccurate soil specific gravity may overestimate bearing capacity, causing dangerous settlements.

What Happens if Cement Specific Gravity Exceeds 3.19?

Values above 3.19 indicate moisture contamination filling cement pores. Hydration begins immediately when cement contacts moisture, producing calcium silicate hydrates that don't contribute to concrete strength. The cement may appear normal but lacks binding capacity. Strength tests reveal deficiency only after considerable time and expense. Always reject cement showing specific gravity above 3.19 or containing visible lumps regardless of age or storage conditions.

Why Use Kerosene Instead of Water for Cement Testing?

Cement rapidly reacts with water through hydration, forming calcium silicate hydrates that alter mass and volume measurements during testing. This reaction makes accurate specific gravity determination impossible using water. Kerosene (specific gravity 0.79) doesn't react chemically with cement, allowing true density measurement. The inert liquid displaces equal to particle volume without chemical interference. Calculations account for kerosene specific gravity differences from water.

Can You Test Specific Gravity for Recycled Aggregates?

Yes, using identical procedures as natural aggregates. Recycled concrete aggregates typically show lower specific gravity due to attached mortar increasing porosity. Expect values 5-10% below natural aggregates from same source. Higher absorption rates accompany lower specific gravity, requiring mix design adjustments. Test each recycled aggregate batch separately as properties vary significantly depending on source concrete quality and processing methods. The difference between rigid and flexible pavement affects which recycled materials work best for specific applications.

How Does Specific Gravity Relate to Aggregate Strength?

Generally, higher specific gravity indicates denser, less porous aggregates with greater strength. Dense particles resist crushing under concrete mixing and structural loads. However, specific gravity alone doesn't guarantee strength. Some lightweight aggregates have engineered strength despite low specific gravity. Always combine specific gravity testing with crushing value and impact tests for complete strength characterization. The relationship holds most reliably for natural aggregates from similar geological sources.